What is one stop PCB assembly? Turnkey pcb assembly services encompass a comprehensive suite of offerings, from circuit board design and component procurement through PCB manufacturing and surface mount assembly to final testing and quality assurance, delivering end-to-end electronic manufacturing solutions for enterprises. This model not only streamlines supply chain management but also significantly enhances production efficiency and product reliability through specialised division of labour and technical collaboration.

Core Processes of One Stop PCB assembly Services

PCB Design Phase: Organisations offering comprehensive services typically employ teams of professional electronic engineers capable of executing circuit board designs according to specific client requirements. This encompasses schematic drafting, PCB layout planning, and circuit simulation to ensure precise, error-free, and efficiently viable circuit designs.

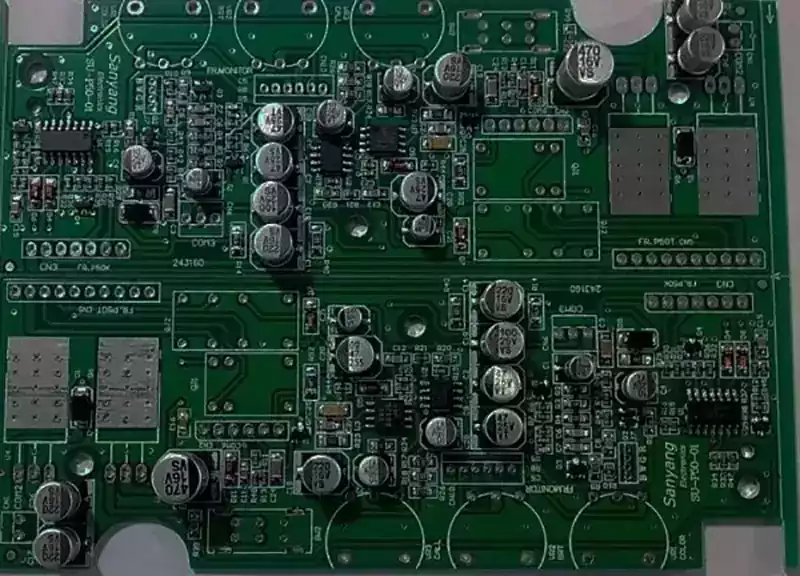

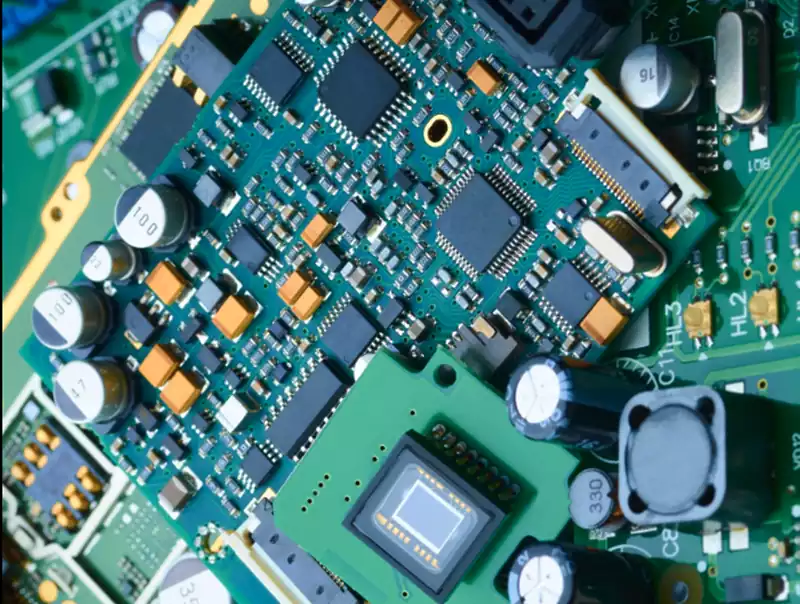

PCB Manufacturing Stage: Following design approval, the one-stop service encompasses the actual production of circuit boards. This process involves selecting suitable substrate materials and executing a series of complex procedures including lamination, drilling, plating, and etching, ultimately yielding PCBs that fully comply with design specifications.

Component Procurement Process: Service providers source and procure high-quality electronic components globally according to the bill of materials specified in the circuit design. This ensures both timely component supply and reliable quality.

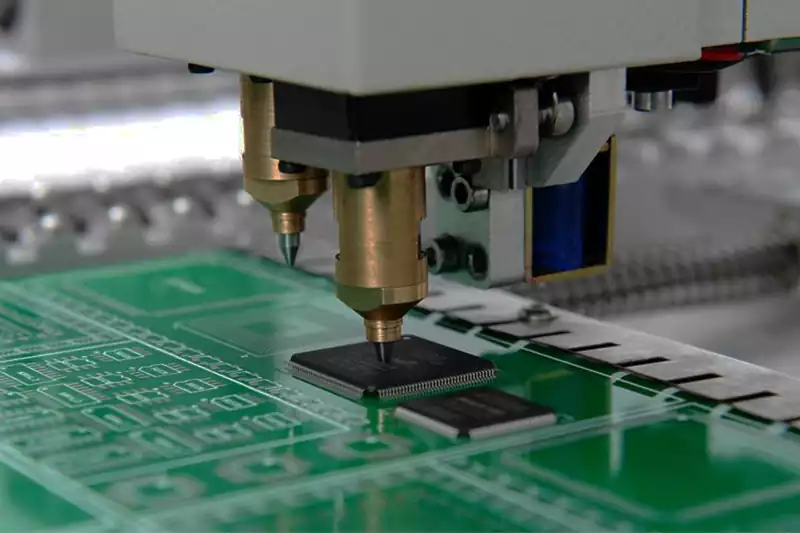

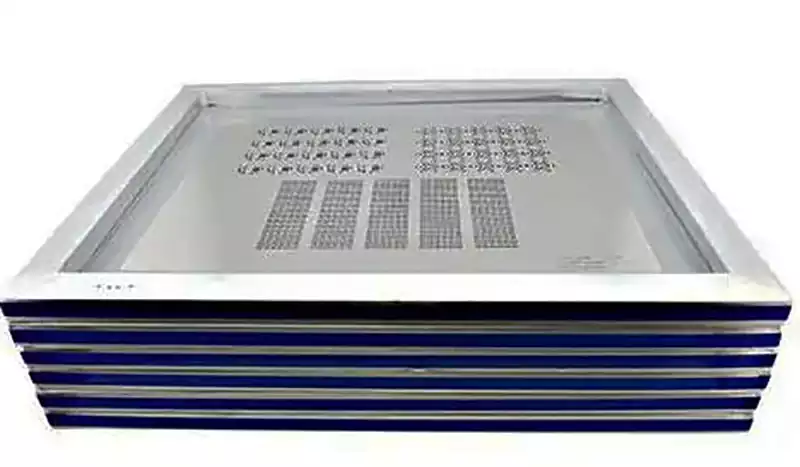

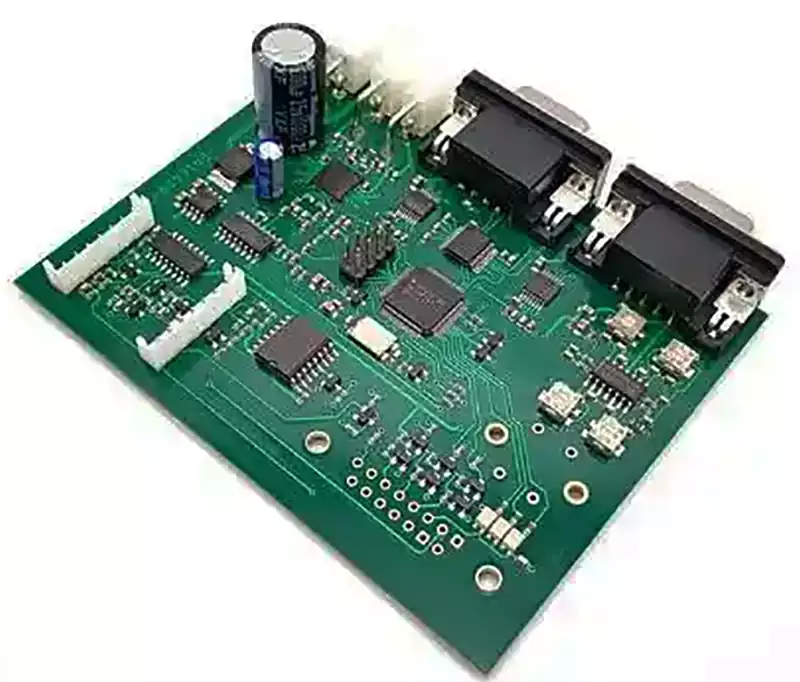

Surface Mount Assembly Process: Once all components are procured, surface mount assembly becomes paramount. Utilising precision placement machines and reflow soldering equipment, components are accurately mounted onto the PCB and soldered in place. Rigorous production techniques and stringent quality control form the core elements ensuring product quality throughout this stage.

Inspection and Quality Control Phase: Processed circuit boards undergo rigorous testing, including functional verification and ageing tests, to guarantee product stability and reliability. Concurrently, the quality control department meticulously monitors every stage of the production process, minimising the likelihood of defective products at source.

Product Assembly and Packaging Process: For complex products requiring further assembly, the one-stop service also provides professional assembly solutions. Final products are packaged using appropriate methods to safeguard them during transportation and storage.

Benefits of turnkey PCB Assembly:

Time Savings

The accumulated advantage of entrusting the entire PCB assembly process to a turnkey manufacturer lies in saving your team valuable time, allowing them to focus on other aspects of the business where their expertise lies. As a client, you need not expend time and effort seeking cost-effective quotes for individual components, enduring the hassle of procuring them, and then integrating all these quotes. From a cost perspective, this proves highly effective as turnkey service pricing is significantly more efficient than bundled services.

Data Traceability

A notable advantage of one stop PCB assembly, beyond time savings, is the centralised management of data across all stages. It reduces communication, negotiation, and verification with multiple suppliers. Simultaneously, every process operates within a unified system, ensuring seamless integration. This avoids costly rework resulting from miscommunication between suppliers. Furthermore, should quality anomalies arise, responsibility is readily assigned, eliminating the need for complex investigations. Should any issues occur, full responsibility lies with the one-stop service provider.

Helping You Identify Issues Early

A key advantage of employing turnkey pcb assembly during the prototype stage lies in its ability to detect any issues early. Indeed, once you share netlist files with the turnkey manufacturer, they can identify errors (if present). These errors can then be corrected during the design phase itself, rather than incurring costly changes when you are ready for full production run, or worse still, after production has been completed and modifications are required.

Supply chain security and enhanced resilience

Uncertainties such as global component shortages and logistical fluctuations are becoming invisible challenges for manufacturing operations. One-stop service providers effectively buffer against external shocks through diversified supplier networks, strategic inventory reserves, and dynamic supply chain monitoring.

For instance, during critical material shortages, providers can swiftly activate contingency plans or substitute components to prevent production halts. This “cushioning effect” proves particularly vital in high-reliability sectors like medical devices and automotive electronics.

Rapid Response to Diverse Demands

The electronics industry undergoes rapid technological iteration. During development, enterprises frequently encounter varied requirements such as small-batch trial production, rapid product updates, and customised manufacturing. Turnkey PCB assembly service providers typically maintain specialised engineering teams. Leveraging their expertise and experience, these teams offer DFM (Design for Manufacturing) optimisation recommendations, helping clients consider production feasibility during the design phase. They also provide efficient rapid prototyping services, enabling clients to visualise product prototypes swiftly. Furthermore, they can assist in optimising BOMs (Bill of Materials) to effectively reduce production costs.

Taking the demand for lightweight IoT devices and consumer electronics as an example, service providers can recommend highly integrated components or meticulously optimise PCB layouts based on product characteristics. This ensures product performance while achieving effective cost control. This flexible, technology-driven service model allows enterprises to focus more resources on core R&D work, avoiding entanglement in intricate production details.

How to Select the Right One Stop PCB assembly Service Provider?

- Assess the Factory’s Level of Specialisation

PCBA manufacturing involves a complex process requiring coordination across multiple departments. A factory’s specialisation level indicates its capability to handle product processing.

1) Availability of Specialised Equipment

PCBA manufacturing necessitates highly specialised machinery, including high-speed pick-and-place machines, multi-zone reflow ovens, AOI inspection systems, and ICT in-circuit testers. These form the foundational equipment for production.

2) Professional Process Management

Beyond equipment, PCBA production demands rigorous process management for quality control. Reputable PCBA manufacturers typically hold certifications like ISO9001 Quality Management Systems and IPC-A-610E Electronic Assembly Acceptance Standards. The presence of SOPs (Standard Operating Procedures) and other documentation guiding employee practices is crucial. Reviewing factory documentation and certifications provides insight into their quality control capabilities.

- Assess service ethos, industry experience, and PCBA quotations

PCBA service providers deliver manufacturing services rather than tangible products. A service provider with strong service ethos proactively assumes responsibility when clients encounter issues, responds swiftly, and resolves challenges. Consequently, a one stop pcb assembly service provider’s service ethos is paramount. This ethos can be gauged by examining the company’s corporate culture and the attitude of its sales personnel towards clients.

The PCBA sector is currently undergoing significant consolidation, with poorly managed providers gradually exiting the market. Years of industry experience thus reflect a manufacturer’s capabilities. Additionally, examine the product portfolio – whether it comprises high-end, mid-range, or low-end offerings, and the specific sectors served. This assessment helps determine compatibility with your own requirements, as suitability remains paramount.

Within the current market landscape, PCBA manufacturing quotations generally exhibit transparency, though price ranges vary considerably—spanning both premium and comparatively low-cost offerings. It must be emphasised, however, that lower pricing does not inherently confer greater advantage.

Certain turnkey pcb assembly manufacturers adhere to sourcing original components through authorised channels and rigorously enforce quality control standards during production. These practices inevitably increase production costs. Conversely, some PCBA providers may cut corners to enhance price competitiveness, ultimately compromising product consistency.

As the adage goes, ‘you get what you pay for.’ When selecting a PCBA service provider, one must thoroughly align their actual requirements and budget to choose a provider offering high value for money that meets their specific needs.

GEO PCB, as a one stop PCB assembly service provider, possesses end-to-end integrated service capabilities spanning design, manufacturing, procurement, component placement, testing, and assembly. It employs high-precision SMT/DIP processes and a rigorous quality control system, supporting multi-stage inspection and full traceability. The company provides rapid engineering response, DFM optimisation, and bespoke technical support; accommodates small-batch trial production and dynamic requirements; enhances cost-effectiveness through economies of scale and flexible billing; and achieves production transparency via its MES system. Furthermore, leveraging accumulated vertical industry expertise, it offers swift post-sales troubleshooting and continuous improvement services, empowering clients to efficiently complete product development and mass production.