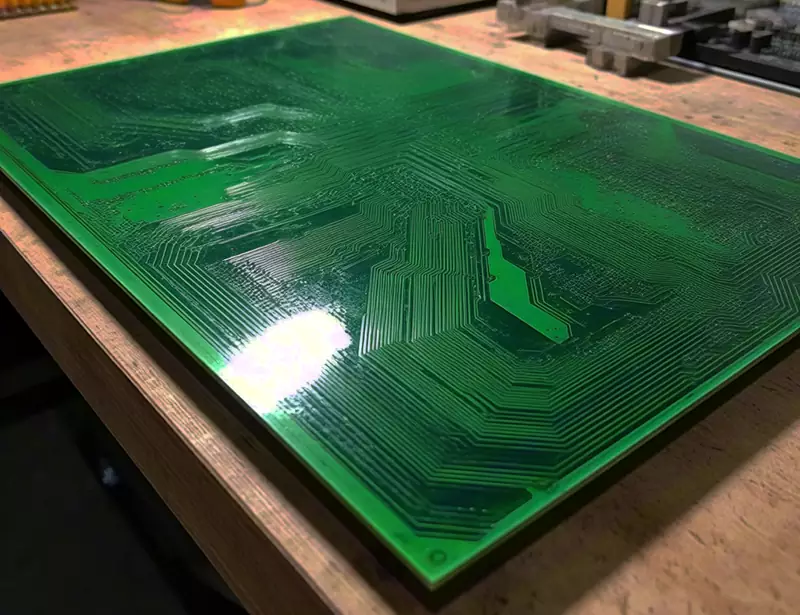

Custom pcb boards, as the name suggests, are specifically manufactured to meet particular requirements and design specifications. They are not merely components within electronic devices but form the very core of a system’s stable operation.

In numerous specialised applications, custom circuit boards prove particularly crucial. Custom pcb boards can be precisely engineered to meet the actual requirements of the equipment, ensuring optimal performance and dimensional compatibility. For instance, in sectors such as aerospace and medical devices, where circuit board performance demands are exceptionally high, custom boards guarantee stable operation under extreme environmental conditions.

Furthermore, custom circuit boards offer the following advantages:

- Enhanced integration: Through bespoke design, more functions can be consolidated onto a single circuit board, thereby reducing equipment size and improving portability.

- Optimised thermal management: For high-power devices, bespoke PCBs enable strategic placement of heat sinks, fans, and other cooling components, preventing overheating during prolonged operation.

- Cost reduction: While initial investment in custom PCB boards is higher, long-term optimisation through streamlined design and elimination of redundant features yields overall cost savings.

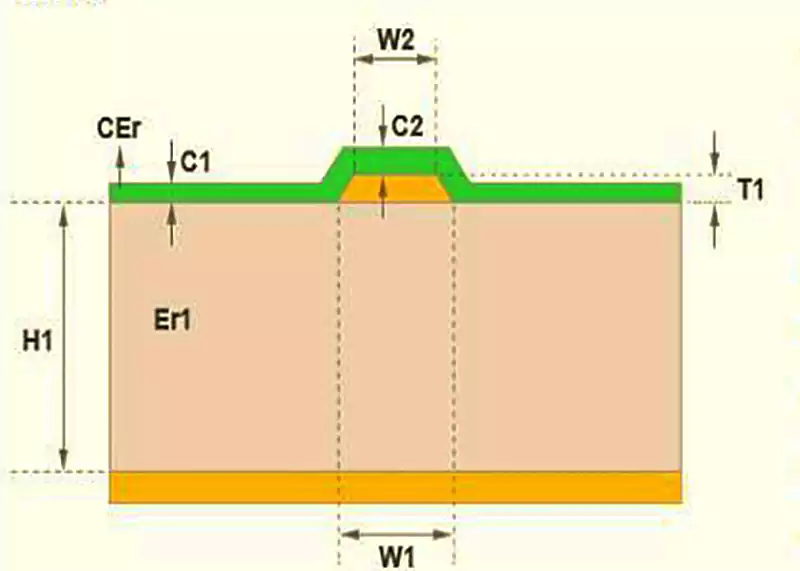

A standard custom PCB board process typically comprises:

- Client submission of design files (Gerber files)

These serve as the manufacturing blueprint and must be flawlessly accurate. - PCB factory engineering review

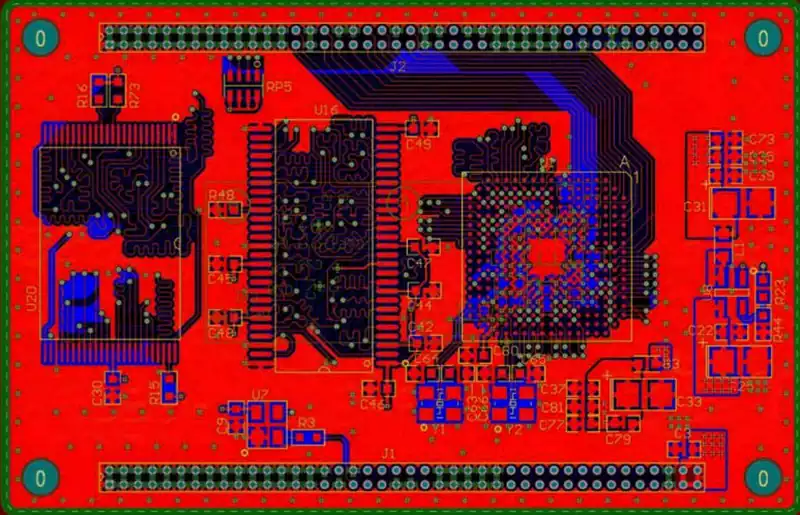

Specialist engineers assess manufacturability, examining parameters such as trace width/spacing, hole placement, and layer alignment. - Prototyping and verification

Small-batch prototypes enable clients to validate board quality, functionality, and compatibility. - Mass production

Large-scale manufacturing is arranged according to client requirements, with meticulous control over every process detail. - Quality inspection

Processes including AOI automatic optical inspection, X-ray analysis, flying probe testing, and functional testing ensure ‘zero-defect’ shipment.

Reputable custom PCB manufacturers typically possess multiple significant advantages: Geopcb boast years of production experience and have accumulated numerous reliable success stories; They maintain comprehensive production facilities utilising advanced automation to guarantee efficiency and quality; Specialised engineering teams assist clients in optimising designs during the planning phase, effectively enhancing yield rates; Capable of supporting rapid prototyping for small batches to meet urgent validation needs, while also handling large-volume orders to ensure stable supply; Additionally, they maintain complete quality certification systems, including ISO9001, UL, and RoHS compliance, providing clients with reliable quality assurance.