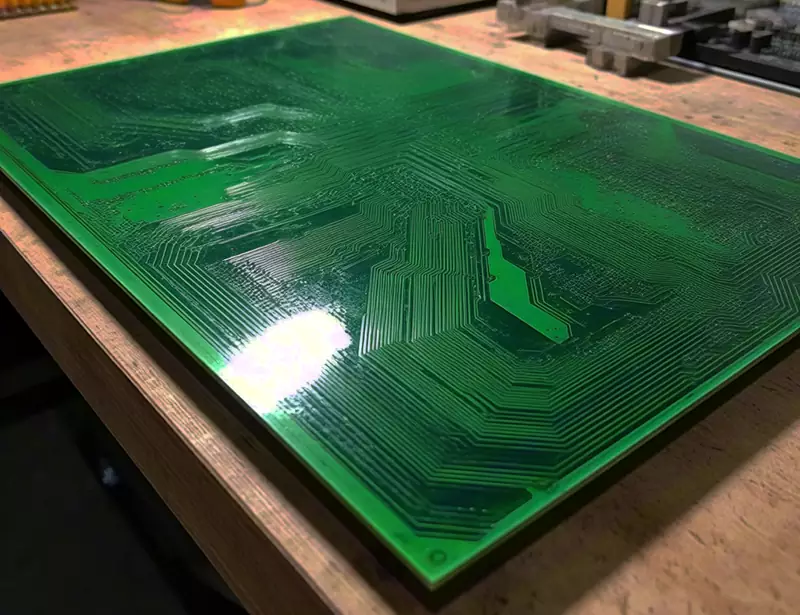

The drone pcb is one of the core components of a drone, serving as its “nerve center.” It connects and controls all electronic components, enabling functions such as signal transmission, data processing, and power management.

Drone pcb typically use either FR-4 epoxy resin substrates or aluminum-based materials. The former offers high mechanical strength and excellent heat resistance, while the latter provides superior heat dissipation. Copper foil, as the conductive material, critically impacts the board’s electrical performance through its quality and thickness.

Core Types of Drone pcb:

Flight Controller Board: Serves as the drone’s “brain,” receiving external commands and sensor data. It processes this information and sends control signals to actuators, enabling autonomous flight and mission execution. Flight control boards typically employ high-density interconnect (HDI) technology with multiple layers to accommodate complex circuit layouts and high-speed signal transmission requirements.

Electronic Speed Controller (ESC) Board: Primarily controls the speed and direction of drone motors, enabling precise flight attitude control. ESC boards handle high currents and power signals, necessitating thick copper or metal substrates to ensure effective heat dissipation and electrical stability.

Power Distribution Board (PDB): Responsible for providing stable power supply to the drone’s various circuit modules, including battery charging, voltage conversion, and current monitoring functions. The PDB board requires high-efficiency power conversion circuits and overcurrent/overvoltage protection features to ensure the drone’s power safety.

Communication Board: Used to enable communication between the drone and the remote controller, ground station, or other devices. Communication boards typically integrate RF modules, antennas, and other components, supporting multiple communication protocols like Wi-Fi, Bluetooth, 4G/5G, etc., to meet diverse connectivity requirements.

Sensor Board: Incorporates various sensors such as accelerometers, gyroscopes, magnetometers, barometers, infrared sensors, etc., to measure the drone’s attitude, position, velocity, and other information. Sensor board design must consider factors like sensor accuracy, stability, and interference resistance to ensure data reliability.

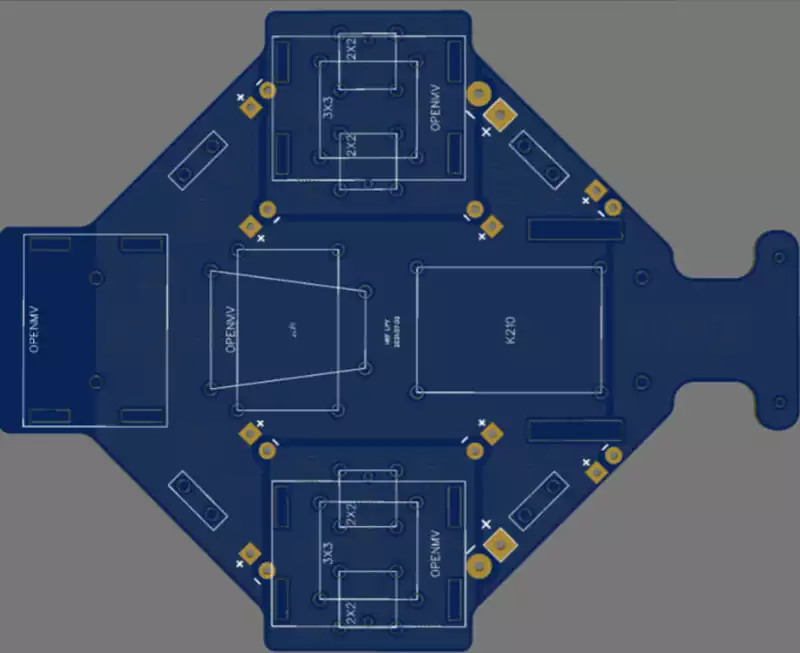

Rigid-Flex PCB: Combines the advantages of rigid and flexible boards, offering the high reliability of rigid boards with the bendability of flexible boards. Rigid-flex PCBs are commonly used in mechanical structures like foldable drone arms and gimbals to enable flexible mechanical movement and circuit connections.

High-Frequency/High-Speed PCB: Supports high-speed data transmission and high-frequency communication functions in drones, such as millimeter-wave radar and 5G communication. Special materials and processes are required to ensure signal integrity and stability while minimizing signal loss and interference.

Three Key Factors for Selecting Drone PCB Layer Count

Foundational Layer Planning Driven by Signal Transmission Complexity

- Lightweight Signal Architecture for Consumer Drones

For consumer applications like aerial photography and recreation, 4-6 layer PCBs meet basic functional requirements:

Typical Application Scenario: A 4-layer board employs a “signal layer-power layer-ground layer-signal layer” stackup to physically isolate flight control MCU, 2.4GHz remote control links, and 5.8GHz video transmission signals. For instance, JDB’s JDB-4L06 solution achieves over 45dB dual-band signal isolation through optimized impedance matching design, effectively suppressing crosstalk.

Performance Expansion Boundaries: 6-layer boards support high-speed signal transmission like USB 3.0 (5Gbps) or MIPI camera interfaces, but require back-drilling to minimize signal stubs and ensure high-speed signal integrity. A consumer drone brand reduced video transmission latency from 120ms to 80ms after adopting a 6-layer board design.

- Multi-protocol integration requirements for industrial drones

Industrial applications like logistics and surveying demand higher PCB layer counts:

High-speed signal management: An 8-layer board with dedicated signal planes simultaneously supports PCIe 3.0 (8Gbps), Gigabit Ethernet, and CAN bus, meeting multi-sensor data fusion needs. A surveying drone adopting an 8-layer board achieved a 300% increase in data transmission bandwidth.

Power Integrity Optimization: A 12-layer board employs a “power-ground-power” sandwich structure with distributed decoupling capacitor arrays, suppressing power noise below 50mV to ensure stable operation of precision equipment like LiDAR. A logistics drone achieved positioning accuracy of ±2cm through its 12-layer board design.

Dynamic Balance of Mechanical Structural Adaptability

- Material Innovation Breaks Weight Constraints

Drones’ demand for lightweight PCBs drives material technology iteration:

High TG FR4 Application: Jiedobang’s TG170 material, developed for 6-layer boards, reduces board weight by 15% compared to traditional materials through glass fiber reinforcement and resin formulation optimization, while passing -40°C to 125°C thermal cycling tests. A long-endurance drone adopting this material achieved an 18% increase in flight duration.

Carbon Fiber Composite Process: For carbon fiber-bodied drones, “prepreg-PCB co-curing” technology reduces PCB thickness to 1.0mm while boosting flexural strength to 300MPa. A folding drone utilizing this process enables reliable 180° folding of its arms.

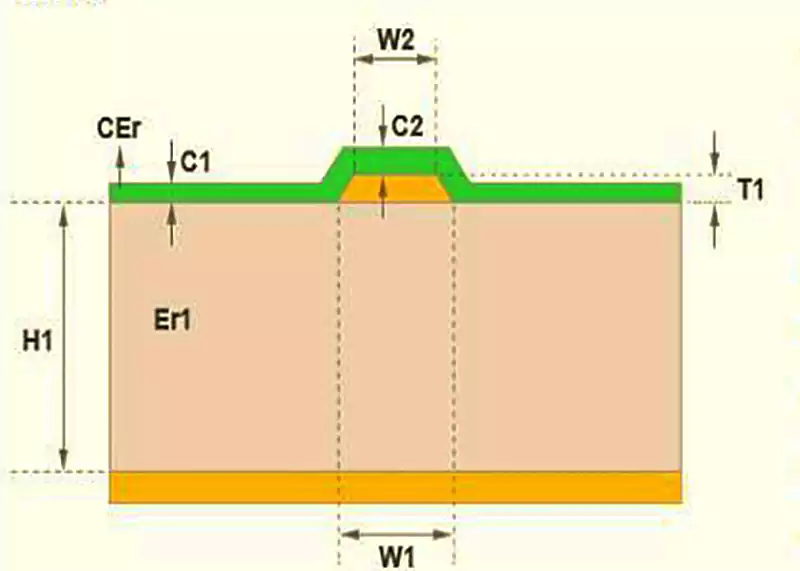

- Synergistic Optimization of Layer Count and Thickness

Weight issues arising from increased layers are addressed through structural innovation:

Rigid-Flex Hybrid Solution: Employing a hybrid structure of 2 flexible layers + 4 rigid layers at folding joints ensures signal continuity while reducing local weight by 40%. A racing drone utilizing this design achieved a 25dB reduction in vibration noise.

Hollow-out weight reduction: Laser-cutting non-wiring areas. A crop-protection drone achieved 22% weight reduction in a 6-layer board while maintaining structural rigidity and doubling vibration resistance.

Cost-Sensitive Design Optimization Pathways

- Cost Reduction Through Laminate Structure Innovation

Blindly increasing layers causes exponential cost growth. Process optimization maximizes cost-effectiveness:

Hybrid Material Solution: Jiedobang’s “high-frequency layer (Rogers 4350B) + standard layer (FR4)” hybrid stacking design reduces 8-layer board costs by 18% while ensuring 5G signal transmission quality. A security drone adopting this solution saw its BOM cost decrease by 12%.

Intelligent Routing Optimization: AI algorithms automatically plan signal traces, boosting routing efficiency by 40% for an agricultural drone PCB. This eliminated the need for two signal layers, directly reducing manufacturing costs.

- Redundant Design Preserves Upgrade Potential

The “N+2” redundancy strategy balances current requirements with future scalability:

Case Study: A surveying drone initially required a 6-layer board. By adopting an 8-layer redundant design, the reserved 2 layers later accommodated an AI edge computing module, eliminating the need for full redesign.

Lifecycle Cost Optimization: Although initial costs increased by 8%, modular upgrades extended the product lifecycle by 3 years, reducing annual unit costs by 22%. An industrial drone pcb manufacturer implementing this strategy saw a 35% increase in customer repurchase rates.