FR4 substrate refers to printed circuit board substrates manufactured using FR4 material. FR4 is a glass fibre reinforced epoxy resin laminate offering excellent mechanical strength and electrical properties. Composed of glass fibre fabric and epoxy resin, the designation ‘FR’ stands for ‘Flame Retardant’, signifying this material possesses favourable flame-retardant characteristics, rendering it suitable for diverse high-risk electronic equipment.

In PCB manufacturing, FR4 substrates typically serve as the carrier material, supporting and connecting diverse electronic components. These components are secured to the substrate via soldering or other methods, thereby completing circuit connections and functional implementation.

Typical Process Flow for FR4 Substrate Manufacturing:

1.Raw Material Preparation

The primary raw materials for FR4 substrates are composite materials consisting of glass fibre cloth and epoxy resin. The glass fibre cloth provides strength and rigidity, while the epoxy resin acts as a binder to bond the glass fibre cloth together. During production, glass fibre cloth and epoxy resin meeting specified requirements must first be selected. High-performance resins are generally employed for the epoxy resin to ensure favourable electrical and mechanical properties.

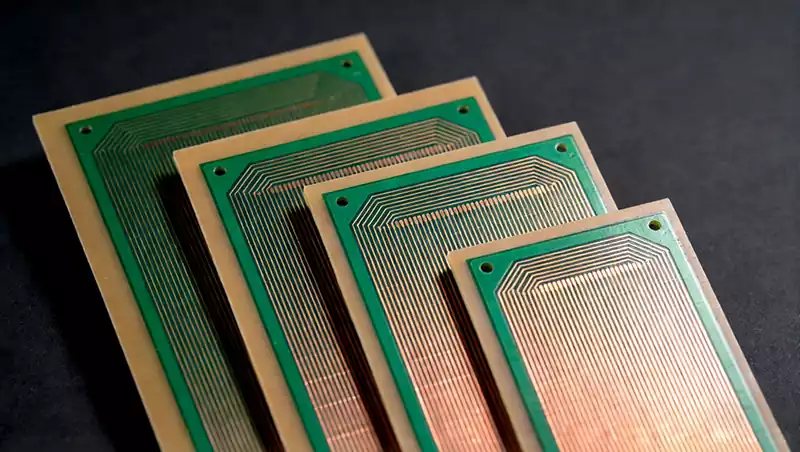

2.Resin Impregnation and Laminating

The selected glass fibre cloth is first impregnated with epoxy resin to ensure thorough saturation. This process is typically conducted under specific temperature and pressure conditions to guarantee uniform resin distribution. The resin-impregnated glass fibre cloth is then fed into a hot press. Under high temperature and pressure, multiple layers of glass fibre cloth are laminated into a robust composite material. This process not only achieves the required density and hardness but also ensures material stability.

3.Cutting and Forming

The resin-impregnated FR4 sheets are cut to standard dimensions, typically determined by subsequent PCB production requirements. The cut FR4 substrates undergo forming to ensure a flat, defect-free surface. Any surface imperfections such as bubbles, creases, or irregularities may compromise subsequent processes and the final circuit board quality.

4.Drilling and Hole Wall Treatment

To facilitate subsequent circuit board connections and component mounting, FR4 substrates undergo drilling. This process creates holes for electrical connections, such as through-holes and vias. High-precision drilling machines are employed to ensure hole size, depth, and positioning meet design specifications. Residual material may remain on drilled hole walls, necessitating deburring and cleaning.

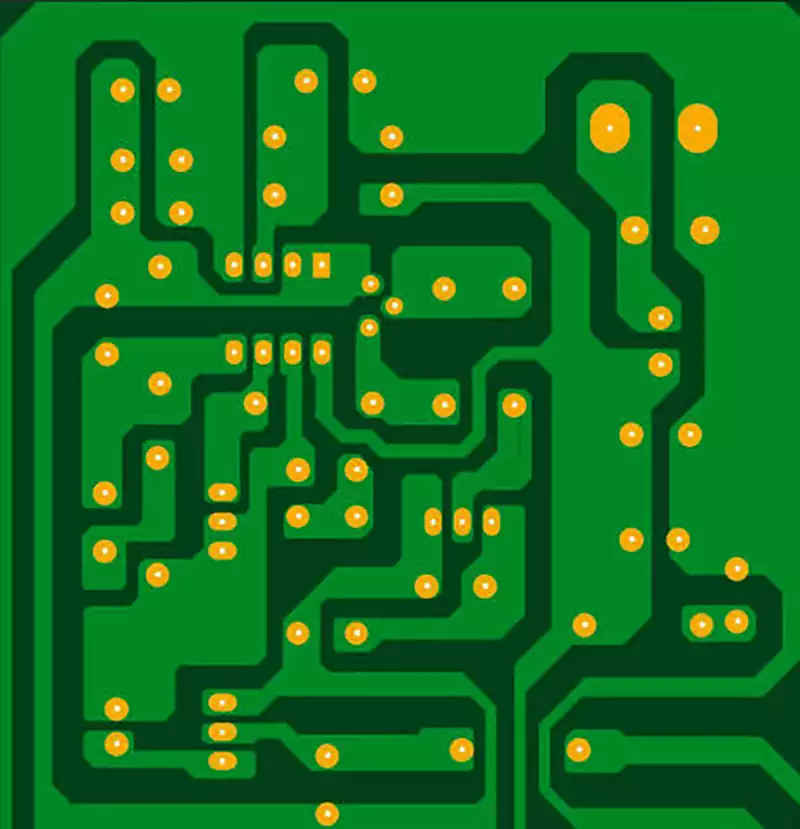

5.Pattern Transfer and Etching

Following the application of a photosensitive film to the FR4 substrate surface, the circuit design pattern is transferred through ultraviolet exposure and development. The exposed substrate undergoes chemical processing to remove unexposed photosensitive film, leaving the patterned design to form the circuit’s metallic layer. Subsequently, excess copper layers are removed via etching, retaining only the required circuit patterns. This process demands high precision to ensure intricate and clear circuit patterns.

6.Metallisation and Plating

Metallisation enhances the conductivity of circuits. Typically, both the outer layers and plated-through holes of PCB boards undergo metallisation. For outer layers, electroplated copper or gold plating is commonly employed to improve electrical performance and corrosion resistance. Plated-through holes also require copper plating to ensure electrical continuity. In certain high-end applications, the FR4 substrate may additionally undergo gold or silver plating to enhance the reliability of electrical connections.

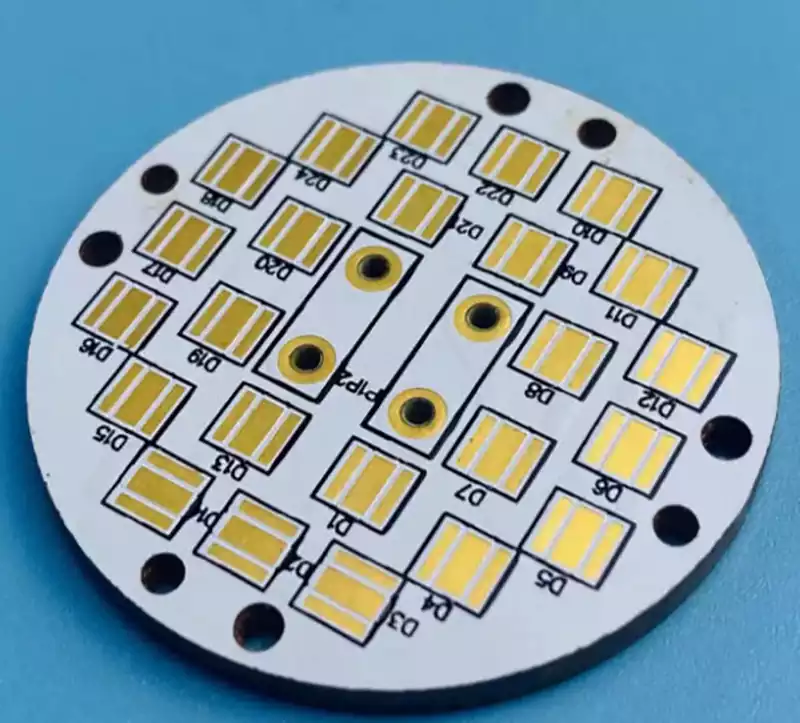

7.Solder Mask and Screen Printing

To prevent short circuits between different metallic areas of the circuit board, the FR4 substrate is typically treated with a solder mask. The function of the solder mask is to protect circuit areas that are not intended for soldering. This protective layer is formed by applying solder mask ink, which is then cured using ultraviolet light. Following solder masking, screen printing is performed to mark various labels and symbols on the PCB circuit board, such as text, icons, and brand logos, facilitating subsequent assembly and maintenance.

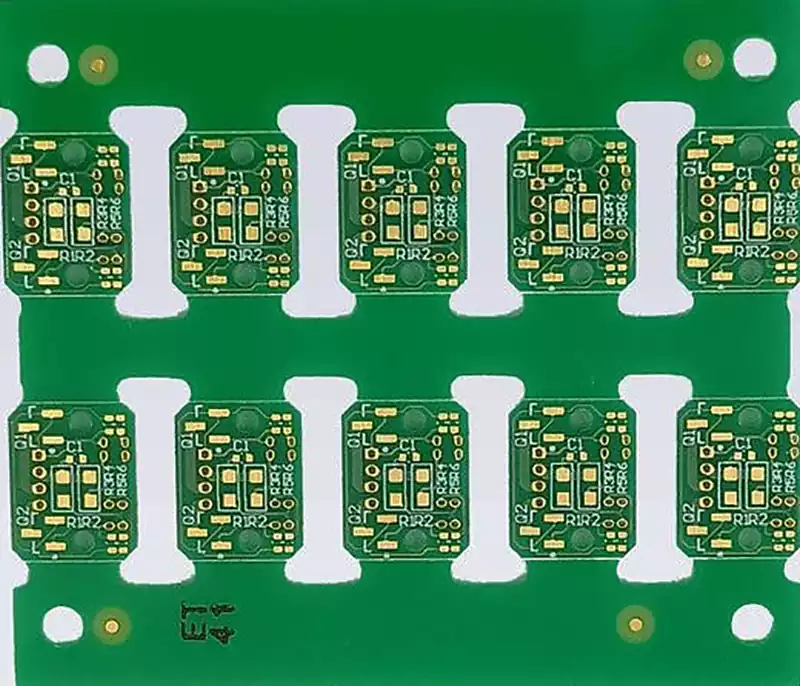

8.Cutting and Depaneling

After completing all processing steps, the FR4 substrate is cut into suitable shapes and dimensions. At this stage, multiple circuit boards may be laminated together and separated using methods such as laser cutting, V-cutting, or mechanical cutting.

9.Electrical Testing and Quality Inspection

Upon completion of the FR4 substrate, the final electrical testing phase commences. This step primarily verifies whether the printed wiring board meets design specifications, such as detecting short circuits or open circuits. Common testing methods include automated testing (ICT), functional testing, and flying probe testing. Following testing, the circuit board undergoes a visual inspection to ensure the absence of defects, scratches, cracks, or other imperfections.

10.Final Processing

Finally, the completed FR4 substrate requires packaging. Depending on requirements, steps such as coating or surface treatment may be undertaken to ensure the PCB’s long-term stability and durability. Once packaged, the substrate can be dispatched to the customer or proceed to downstream assembly stages.

Applications of FR4 Substrates

Consumer Electronics

Within the consumer electronics sector, FR4 substrates are frequently employed in printed circuit boards for devices such as smartphones, tablets, and televisions. Their stable electrical properties and robust mechanical strength enable them to meet the demands for high-performance circuit boards in these appliances.

Automotive Electronics

With the advancement of smart vehicles and electric cars, automotive electronics face increasing complexity and demands. FR4 substrates, renowned for their superior high-temperature resistance and anti-interference capabilities, are extensively employed in onboard electronic systems such as battery management systems, navigation systems, and in-vehicle entertainment systems.

Industrial Control

Within industrial automation equipment, FR4 substrates frequently serve as core components in various sensors and motor control boards. Their high strength and durability ensure stable operation during prolonged use.

Medical Equipment

Owing to their reliable performance and precision machinability, FR4 substrates are extensively employed in printed circuit boards for medical devices, including patient monitoring equipment, surgical instruments, and diagnostic apparatus.

Aerospace

Within aerospace applications, the stability and safety of electronic equipment are paramount.FR4 substrates, with their vibration resistance and high-temperature tolerance, find widespread use in the electronic systems of spacecraft and satellites.

FR4 substrates, owing to their superior performance, find extensive application across electronic devices in diverse industries. Whether in consumer electronics, automotive electronics, industrial control systems, medical equipment, or aerospace applications, FR4 substrates play an indispensable role. As electronic technology continues to advance, FR4 substrates will persist in fulfilling critical functions within various high-performance devices, driving innovation and progress in modern electronic products.