From early vacuum tube equipment to today’s 5G communication terminals and industrial control systems, printed circuit boards (PCBs) serve as the core carrier for electronic devices, with their substrate technology undergoing multiple generations of renewal. Among numerous PCB substrates, FR4 substrate has consistently held a dominant position, finding extensive application across diverse scenarios such as mass production of consumer electronics and customised industrial equipment. Its enduring ‘evergreen’ status within the industry for decades is no mere market coincidence, but rather stems from a balanced system it has established across three core dimensions: performance, cost, and manufacturing process. Its high cost-effectiveness logic derives from mature compatibility across the entire industrial chain and precise coverage of the vast majority of application scenarios.

Balanced Performance

The primary reason for FR4 substrate’s enduring widespread adoption lies in its balanced performance metrics, with no significant shortcomings. In practical applications, it avoids the excessive cost associated with pursuing extreme performance in any single dimension, while effectively meeting the core performance requirements for substrates in most electronic devices.

Compositionally, FR4 substrates primarily consist of epoxy resin and glass fibre cloth. During manufacturing, these materials are tightly bonded through hot-press forming, creating a composite substrate structure. This unique composition endows FR4 with stable multi-faceted properties. Electrically, it fulfils fundamental requirements for signal transmission and insulation, ensuring stable and reliable performance during device operation. Mechanically, it possesses adequate strength and toughness to withstand external forces without deformation or damage, providing stable mechanical support for electronic components. Regarding thermal resistance, it maintains performance stability under elevated temperatures without rapid degradation or failure, ensuring reliable operation within normal working temperature ranges. Combining these performance characteristics, FR4 plate strikes an excellent balance between practicality and cost-effectiveness, establishing itself as an ideal substrate solution for the electronics industry.

Electrical Properties

Regarding electrical characteristics, FR4 substrates exhibit a stable dielectric constant (Dk) between 4.2 and 4.8, with a loss factor (Df) below 0.02. This fully meets the requirements for medium-to-low-speed signal transmission, making it suitable for mainstream applications such as consumer electronics (e.g., mobile phones, computer peripherals), general industrial equipment (e.g., sensors, controllers), and household appliances. For high-frequency communication scenarios, while conventional FR4 substrates do not match the performance of specialised substrates like polytetrafluoroethylene (PTFE), modified variants (such as high glass transition temperature (Tg) FR4 or low-loss factor FR4 variants), its dielectric constant can be optimised to 3.8–4.2, with loss factor reduced below 0.015. This enables adaptation to 5G sub-6GHz communication requirements, achieving a technological breakthrough in cost-effective high-end application compatibility. Industry data indicates that within 5G base station auxiliary control modules, FR4 substrates account for 85% usage, significantly surpassing the 15% application share of specialised substrates.

Mechanical Properties In terms of mechanical properties, FR4 plate exhibit a flexural strength exceeding 300 MPa and a tensile strength surpassing 150 MPa. This enables them to withstand drilling, cutting, and bending operations during PCB manufacturing, while also meeting mechanical impact requirements during electronic device assembly and transportation. Compared to the brittleness of ceramic substrates and the deformation susceptibility of aluminium substrates, FR4 offers superior structural stability. This eliminates the need for additional reinforcement processes, effectively reducing overall production costs. Under standard environmental conditions, dimensional stability errors for FR4 substrates can be controlled within 0.1%, ensuring precise soldering accuracy for microcomponents and minimising product failures caused by substrate deformation.

Thermal Resistance

Regarding thermal resistance, standard FR4 plate exhibit a glass transition temperature (Tg) of approximately 130°C, while high-Tg variants can exceed 170°C. This enables stable performance under short-term high-temperature impacts during Surface Mount Technology (SMT) reflow soldering (peak temperature 260°C). Long-term operating temperatures remain stable within the 105°C to 150°C range, covering the operational environments of most electronic devices. For high-temperature applications such as automotive electronics, FR4 substrates modified with specialised resins achieve long-term thermal resistance exceeding 180°C. This performance comes at a cost representing one-third that of ceramic substrates and half that of polyimide substrates.

Cost Control

The high cost-effectiveness of FR4 substrates stems primarily from the maturity of the entire industrial chain. From raw material supply and production process implementation to capacity expansion and waste recycling, precise cost control has been achieved at every stage, establishing a ‘cost-performance advantage’ that other substrates struggle to match.

Adequate Supply, Stable Pricing

Regarding raw materials, the core components of FR4 plate—epoxy resin and glass fibre cloth—are both commodities characterised by ample market supply and minimal price volatility. Global annual production of epoxy resin exceeds 10 million tonnes, while glass fibre cloth capacity surpasses 20 billion square metres. This large-scale mass production effect keeps raw material unit costs consistently low. Data indicates that standard FR4 substrate raw material costs range from 20 to 30 yuan per square metre, whereas PTFE substrates incur costs of 200 to 300 yuan per square metre, with aluminium substrates costing between 80 and 100 yuan per square metre. Furthermore, FR4 boards benefit from extensive procurement channels independent of scarce resources, effectively mitigating supply chain risks and procurement expenses.

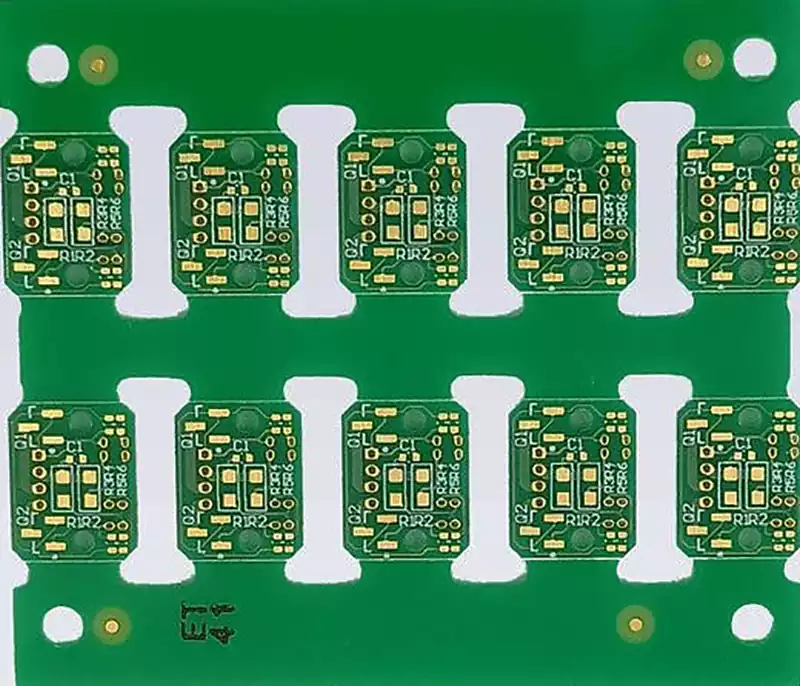

Standardised Automation, High Yield Rates

In terms of production processes, FR4 board manufacturing has achieved high levels of standardisation and automation. Core processes such as hot pressing, cutting, and drilling yield rates exceed 98%, with scrap rates below 2%. In contrast, ceramic substrate sintering yields approximately 85%, while PTFE substrate forming processes are complex, yielding rates below 90%. High yield rates directly reduce unit manufacturing costs, while standardised processes minimise customisation requirements for production equipment. Investment costs for a conventional FR4 production line are approximately ¥5 million per line, whereas specialised substrate lines typically exceed ¥20 million per line. This lowers industry entry barriers for manufacturers, expands FR4 board production capacity, and fosters a virtuous cycle of ‘economies of scale – cost reduction’.

Excellent recyclability generates additional revenue

Regarding recycling, FR4 substrates demonstrate superior recyclability compared to most specialised substrates. Discarded FR4 PCBs can undergo mechanical crushing and chemical de-gluing to separate copper foil and glass fibre. Copper foil recovery rates exceed 95%, while glass fibre can be repurposed into construction materials, insulation, and other applications, enabling resource reuse. This not only reduces environmental disposal costs but also generates additional resource recovery revenue for manufacturers, further enhancing overall cost-effectiveness. Industry data indicates FR4 PCB recycling yields an added value of approximately 5–8 yuan per kilogram, whereas PTFE substrates yield near-zero recycling value, and ceramic substrates incur recycling costs exceeding their material worth.

Practical characteristics lowering production barriers

The enduring prominence of FR4 substrates also stems from their high compatibility with diverse PCB manufacturing processes. Whether for single/double-sided PCBs, multilayer PCBs, flexible PCBs, or rigid-flex PCBs, FR4 substrates offer seamless adaptability without requiring manufacturers to significantly alter production workflows. This further reduces production and application costs while enhancing market applicability.

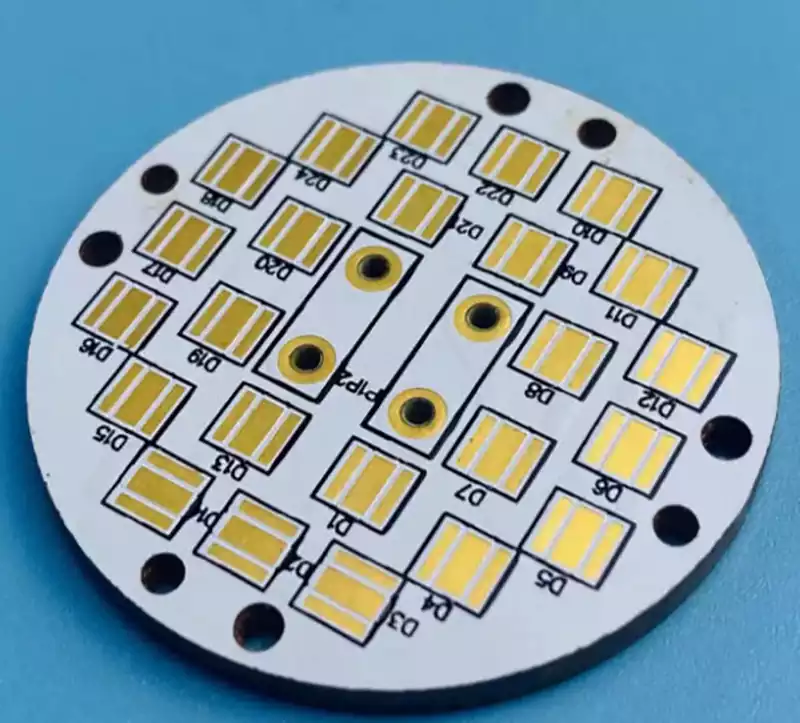

Mature Laminating Process

In multilayer PCB production, FR4 substrates employ a well-established laminating process capable of fabricating boards exceeding ten layers. Their strong interlayer bonding strength, exceeding 1.5 N/mm, ensures stable signal transmission within multilayer boards. In contrast, flexible substrates involve complex lamination processes with higher interlayer delamination risks, necessitating specialised bonding materials and equipment. Ceramic substrates face challenges such as sintering deformation and insufficient interlayer alignment precision during multilayer fabrication, hindering large-scale production. In sectors with high demand for multilayer PCBs—such as consumer electronics and industrial control—FR4 substrates’ process compatibility makes them the preferred solution.

Surface Treatment Processes

Regarding surface treatment compatibility, FR4 substrates accommodate multiple finishes including Hot Air Solder Leveling (HASL), electroless gold plating, electroless silver plating, and Organic Solderability Preservative (OSP). Optimal solutions can be selected based on application requirements. For instance, electroless gold plating enhances oxidation resistance and solder reliability, making it suitable for high-end electronics, while OSP offers cost-effective mass production for consumer electronics. This compatibility enables manufacturers to produce products of varying quality requirements without changing substrates, significantly enhancing production line flexibility while reducing equipment investment and process adjustment costs.

Component Soldering Process

Moreover, FR4 substrates are perfectly compatible with various component soldering processes. Whether through-hole technology (THT) or surface mount technology (SMT), they ensure robust solder joints and stable electrical connections. Its moderate surface roughness enhances solder wettability, enabling soldering defect rates to be controlled below 0.1%—significantly lower than the 0.5% for ceramic substrates and 0.3% for flexible substrates. This low defect rate further reduces rework costs and boosts production efficiency.

Mitigating Risk, Enhancing Efficiency

Through decades of development, FR4 boards have established comprehensive international and domestic standards. Examples include the IPC-4101 standard issued by the International Printed Circuit Association and China’s national standard GB/T 4721, which clearly define key aspects such as performance metrics, production processes, and quality inspection for FR4 substrates. This standardisation delivers two core advantages: firstly, it reduces communication costs and quality risks for both suppliers and buyers; Secondly, it enhances product interchangeability and universality, cementing its position as the industry standard.

Simplifying Inspection Processes, Reducing Cost Cycles

From the procurement perspective, standardised performance metrics eliminate the need for comprehensive testing of every batch of FR4 plate. Instead, manufacturers can conduct random sampling of key indicators (such as Tg value, dielectric constant, and insulation resistance) against established standards to ensure substrate quality, significantly reducing inspection costs and procurement lead times. By contrast, standards for specialised substrates remain fragmented, with considerable performance variations between suppliers. Manufacturers must invest substantial effort in supplier audits and product testing, increasing procurement costs and risks.

Providing clear guidelines to enhance design efficiency

From the design perspective, standardised FR4 parameters offer PCB designers explicit design references. Designers can directly utilise standard parameters for circuit layout, impedance matching calculations, thermal design, and other tasks without conducting complex substrate performance tests, effectively boosting design efficiency. Furthermore, standardised FR4 products exhibit strong interchangeability. Even when switching suppliers, product design compatibility remains unaffected, mitigating risks associated with supply chain volatility. This characteristic proves particularly crucial in the mass production of consumer electronics, ensuring consistency across different batches and bolstering brand reputation.

Defining Testing Standards to Safeguard Product Quality

From a quality control perspective, a comprehensive standards framework provides clear benchmarks for FR4 substrate testing. Specific pass criteria are established for measurements such as insulation resistance, temperature resistance, and mechanical strength, effectively preventing non-compliant products from entering the market. This standardised quality management system not only mitigates manufacturers’ quality risks but also enhances downstream customers’ confidence in FR4 reliability, thereby expanding market demand.

Continuously Adapting to Emerging Demands

The enduring relevance of FR4 substrates stems not from technological stagnation, but from continuous technical iteration that adapts to emerging application requirements, thereby extending its lifecycle. With the rapid development of emerging fields such as 5G, automotive electronics, and industrial internet, the market demands higher performance from PCB substrates. Through modification and upgrading, FR4 substrates have achieved a ‘low-cost + high-performance’ technological breakthrough, further reinforcing their cost-effectiveness advantage.

Modified FR4 Meets Signal Transmission Demands

Addressing the high-frequency requirements of 5G communications, the industry has developed modified FR4 substrates with high Tg and low Df. By optimising epoxy resin formulations and employing low-loss glass fibre cloth, their dielectric constant can be reduced to below 3.8, with a loss factor under 0.012. This enables compatibility with 5G Sub-6GHz band signal transmission requirements, at a cost merely one-quarter to one-third that of PTFE specialty substrates. In applications such as 5G base station RF front-end modules and smartphone antenna substrates, modified FR4 substrates have seen widespread adoption, establishing themselves as the optimal technical solution balancing performance and cost.

Automotive-grade FR4 emerges

Addressing automotive electronics’ demands for high-temperature resistance and reliability, automotive-grade FR4 plates have achieved industrial-scale application. These substrates exhibit moisture-heat resistance and anti-ageing properties, with a glass transition temperature (Tg) exceeding 180°C and long-term operational stability at 150°C. They demonstrate no significant performance degradation after 1000 hours of moisture-heat ageing testing at 85°C/85% RH, making them suitable for harsh environments like engine compartments and chassis. Compared to conventional FR4 boards, automotive-grade FR4 substrates incur only a 10%–15% cost increase while meeting automotive electronics reliability requirements, offering significantly better cost-performance than ceramic or polyimide substrates.

High-insulation strength FR4 ensures safety

Addressing the high-voltage demands of new energy equipment, high-insulation strength FR4 substrates have achieved a technological breakthrough. With a breakdown voltage exceeding 40kV/mm and volume resistivity surpassing 10¹⁴Ω·cm, they guarantee insulation safety for high-voltage equipment such as new energy vehicle charging stations and photovoltaic inverters. At just one-fifth the cost of high-voltage ceramic substrates, FR4 plate has become the mainstream substrate choice in the new energy sector.

The enduring prominence of FR4 substrates within the PCB industry stems from their precise equilibrium between performance, cost, and manufacturing processes. Rather than pursuing singular extremes, they comprehensively address the vast majority of application scenarios; rather than relying on scarce resources, they achieve cost control through matured end-to-end supply chains; rather than being confined to single manufacturing methods, they accommodate diverse production requirements. nor does it adhere rigidly to traditional standards, instead adapting to emerging scenarios through iterative upgrades. This comprehensive equilibrium system establishes FR4’s unparalleled cost-performance advantage.

Amidst the continuous evolution of electronic technology, specialised substrates may capture market share in specific high-end applications. However, FR4 substrate will maintain its dominant position within the PCB board industry due to its balanced performance, controllable costs, mature manufacturing processes, and ongoing capacity for advancement.