Drone antennas are radio antennas specifically designed for communication and control of unmanned aerial vehicles. These antennas receive and transmit wireless signals, ensuring stable communication between the drone and ground stations or other devices.

Types and Functions of Drone Antennas

- Basic Classification

Drone antennas are primarily categorised into omnidirectional antennas, directional antennas, and smart antennas based on application requirements. Omnidirectional antennas are suitable for communication scenarios requiring all-round coverage, such as ground control communication during drone take-off and landing. Directional antennas concentrate energy in specific directions, enhancing the efficiency and stability of long-distance communication, and are commonly used for drone inspection, surveying, and mapping tasks. Smart antennas dynamically adjust beam direction to suppress multipath effects and avoid interference, improving communication quality in complex environments. - Core Functions

The primary functions of UAV antennas encompass signal transmission and reception, frequency band coverage, polarisation matching, and gain control. Signal transmission and reception constitute the antenna’s fundamental capability, responsible for transmitting data from the UAV to the ground station while receiving commands from it. Frequency band coverage determines the operational frequency range of the antenna, with selecting the appropriate band being critical for different application scenarios. Polarisation matching ensures optimal signal transmission efficiency and minimises signal loss. Gain control optimises communication range and interference resistance by adjusting the antenna’s radiation intensity.

Drone antennas typically comprise several key components: the radiator, transmission line, and protective housing.

- Radiator: The radiator is the antenna’s most critical component, converting electromagnetic energy into radio waves in space or vice versa. This process underpins the drone’s long-range communication capability.

- Transmission Line: Connecting the radiator to the UAV’s communication system, the transmission line conveys signals between these components. Its quality and performance directly impact signal transmission efficiency and stability.

- Protective Housing: Enveloping the radiator and transmission line, the protective housing primarily safeguards the antenna against damage during flight.

Common Materials and Processes for Drone Antennas

Common Materials:

FR4 (Fibre-Reinforced Polymer):

Characteristics: FR4 is a widely used printed circuit board (PCB) material offering excellent electrical insulation, mechanical strength, and machinability. Suitable for medium- and low-frequency communications.

Applications: Commonly used in standard microstrip antennas and certain low-cost small drone antennas.

PTFE (Polytetrafluoroethylene):

Characteristics: PTFE exhibits exceptional high-temperature resistance, corrosion resistance, and low loss properties, making it suitable for high-frequency signal transmission. Compared to FR4, PTFE possesses a lower dielectric constant, delivering superior signal transmission performance.

Applications: Frequently employed in high-performance microstrip antennas or drone applications demanding minimal signal loss, particularly in high-frequency domains such as 5G and satellite communications.

Aluminium Plate:

Characteristics: Aluminium is lightweight with excellent electrical conductivity, commonly used as the antenna backplane for large-scale or directional antennas to aid reflection and gain enhancement.

Applications: Typically employed in structural components of long-range directional antennas, such as satellite communication systems.

Copper-based Materials:

Characteristics: Copper exhibits low electrical resistance and excellent conductivity, making it ideal for high-frequency and ultra-high-frequency antenna designs to minimise signal loss.

Applications: Commonly used in high-frequency antennas, such as phased array systems, where superior signal transmission performance is critical.

Composite Materials:

Characteristics: Composite materials (e.g., carbon fibre or glass fibre reinforced plastics) offer favourable strength-to-weight ratios and corrosion resistance, making them suitable for drone antenna housings or support structures.

Applications: Employed in fabricating lightweight yet structurally robust external components for drone antennas.

Common Manufacturing Processes:

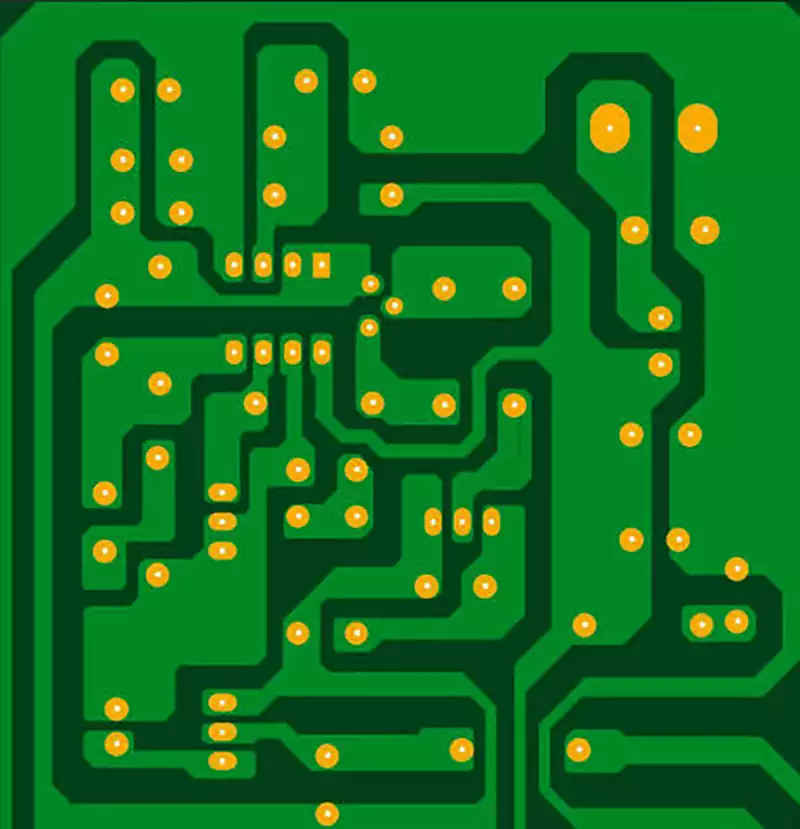

Microstrip Technology:

Principle: Microstrip antennas transmit signals by connecting the antenna conductor to the substrate’s metal layer via microstrip lines. Microstrip antennas offer advantages of simple structure, ease of integration, and straightforward production.

Applications: Widely employed in communication systems for small and micro drones, particularly suited for applications with stringent weight and volume constraints.

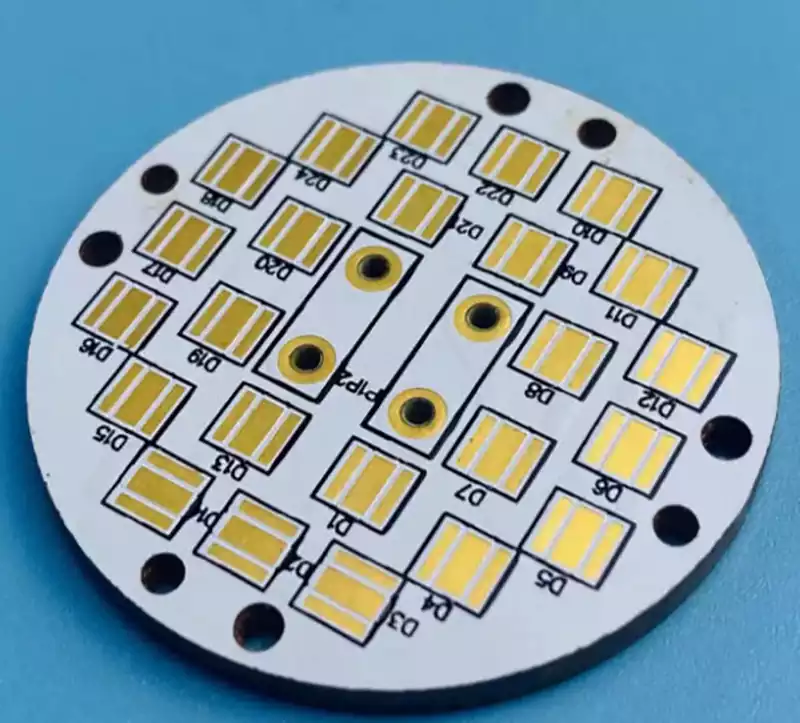

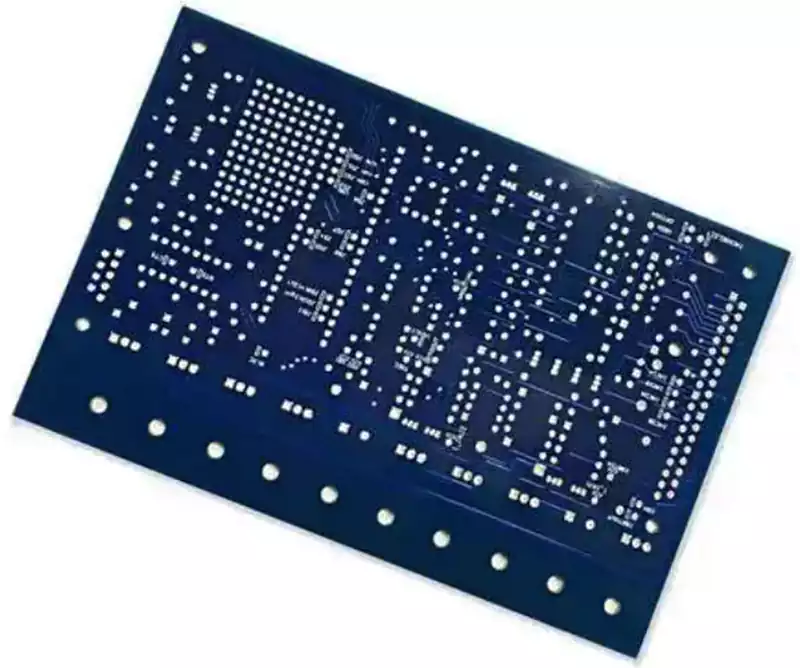

Printed Circuit Board (PCB) Manufacturing Process:

Principle: Utilises PCB manufacturing techniques to print antenna patterns onto substrates, commonly used for microstrip antenna production. This process enables mass production via automated lines at relatively low cost.

Applications: Suitable for antennas operating in lower frequency bands or for drone applications demanding specific antenna dimensions and shapes.

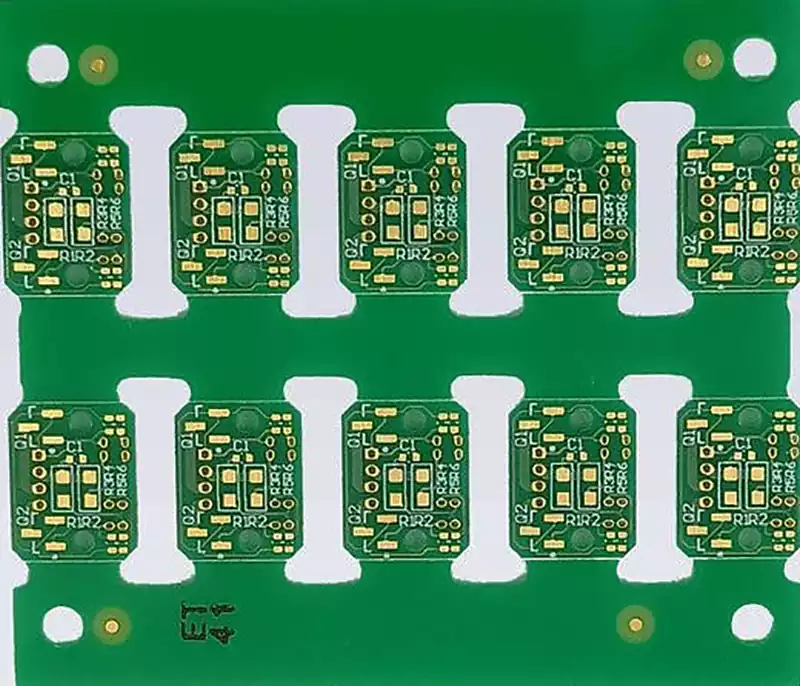

Surface Mount Technology (SMT):

Principle: Utilises surface mount technology to mount antenna components (such as radio frequency components) onto a PCB, assembled with precision by automated placement machines.

Applications: This process suits compact UAVs, particularly those requiring antenna systems with integrated multifunctional capabilities.

Metal Forming and Milling Processes:

Principle: Precisely fabricating metal antenna components via milling or laser cutting techniques, particularly suited for directional antennas and large-scale antenna production.

Applications: Typically employed for larger antennas demanding high gain, such as satellite antennas for long-range communication or high-gain antennas.

Phased Array Technology:

Principle: Phased array antennas rapidly adjust beam direction by modulating the phase of multiple antenna elements. Manufacturing requires high-precision array design and integration techniques.

Applications: Widely employed in advanced UAV systems, particularly for high-frequency communications or radar applications requiring dynamic beam steering.

3D Printing Technology:

Principle: Directly fabricates antenna geometries using 3D printing, suitable for complex structures or customised requirements. Materials employed may include plastics, metals, or composites.

Applications: Suited for rapid prototyping and small-batch custom production, particularly in antenna design for special-purpose UAVs.

Drone antennas play a critical role in ensuring stable communications and mission execution. With ongoing technological advancements, antenna design and manufacturing processes continue to be optimised to meet increasingly efficient and complex application demands. In the future, UAV antennas will assume an even more pivotal role across diverse sectors.