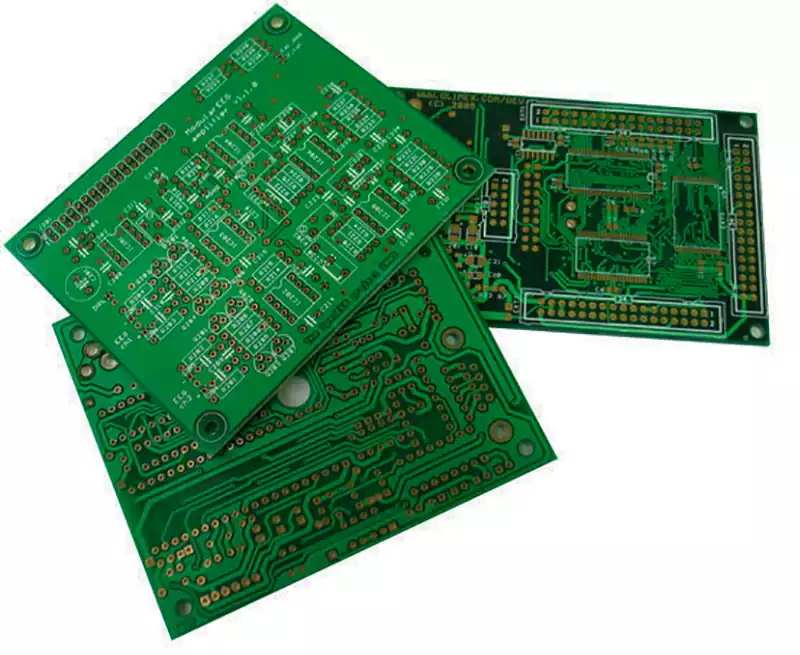

The PCB prototype is essentially an early sample of the product, with the purpose of testing the design concept and examining its feasibility. Although most prototypes are only made to test basic user functions, PCB board prototype stills need to have some degree of functionality, as PCB prototyping is done to test the overall functionality of the design.

A printed circuit board prototype or low-cost PCB board prototype is a small device used to connect electronic components to ensure the smooth operation of a product. This process determines whether the proposed PCB design will be executed as expected, thereby revealing any possible defects and enabling the designer to make any necessary changes. At this stage, any other improvements or alternative solutions that the designer may have thought of were also introduced. The large-scale production of any new product cannot be separated from circuit board prototyping services, which cannot be simply started without a prototype design phase.

PCB board prototype design may not necessarily discover any defects, as sometimes the design is perfect. After completing the PCB prototype board, the electronic components of the product will be connected into PCA (Printed Circuit Assembly), usually with the help of soldering. Then, manufacturers or customers can provide their opinions on the PCB and any other suggestions/improvements they may have. PCB prototype service designers should always be prepared for any possible outcome, so any rework at this stage should not be considered an additional cost. Skipping prototype design and participating in large-scale production of PCB prototype boards will only lead to their failure, and it will definitely be catastrophic in terms of wasting energy, time, and money.

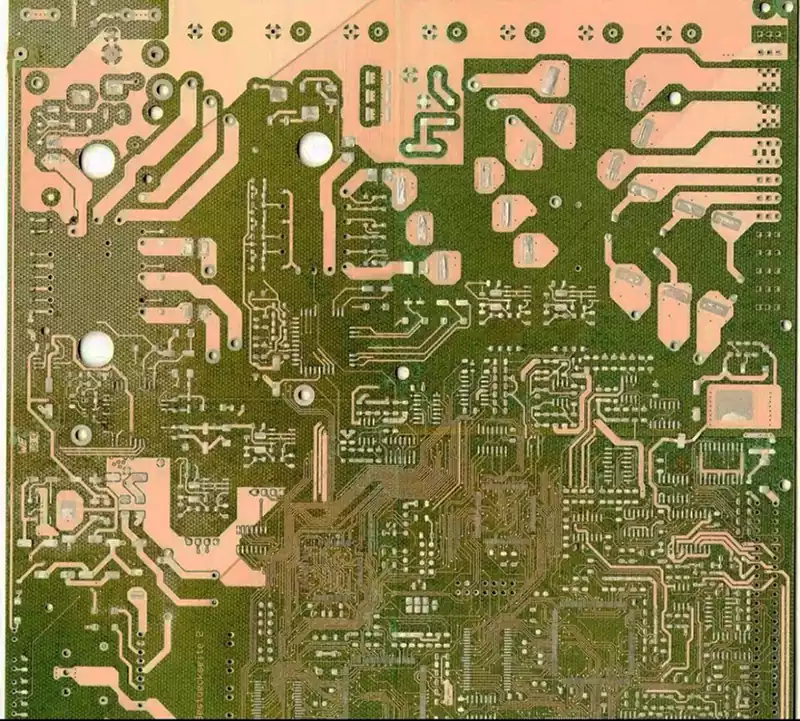

The following are the general stages of printed circuit board prototype production. The first type is called breadboard testing or proof of principle. This will check whether the logic behind the PCB prototype board can be implemented. The next step is to check the expected size (preferred size) of the PCB prototype board. After this stage, a visual model is generated, and if approved, the final stage of functionality and appearance begins. The achievement achieved at this moment is the closest approximation to the actual PCB prototype board. Usually, in circuit board prototype design, the simulation of current in the circuit board and the state of the circuit are the two most important processes. Actual components and materials can only be implemented for the final model or prototype before the simulation system works as required.

The advancement of technology and computerization has paved the way for convenient production of PCB/s worldwide. Prototype design is a modern system used for economically and efficiently manufacturing PCB boards, primarily consisting of major electronic components.

Actively introducing printed circuit board prototype manufacturers, prototypes are not ordinary products like copiers, and users can easily use them. PCB prototype boards need to be researched before use. As a modern and reasonably priced project and investment, it requires a lot of experience to judge the equipment before obtaining it.

Key specifications for PCB board prototype production

- Size: PCB cost is related to surface area, and space should be planned reasonably to reduce costs. At the same time, attention should be paid to irregular shapes, which can easily cause material waste. Small rectangular PCBs have higher costs,

- Layers: Layers are an important manifestation of complexity, and multi-layer PCBs are like stacked highways, providing routing for overlapping electrical connections.

- Material type: The commonly used FR-4 material is composed of glass epoxy resin. When designing high-speed or RF boards, attention should be paid to the dielectric properties and thickness of the material.

- Circuit board thickness: Select the core size based on the number of copper layers to determine the thickness. Special environments may require specific thicknesses, with a minimum of 0.4 millimeters.

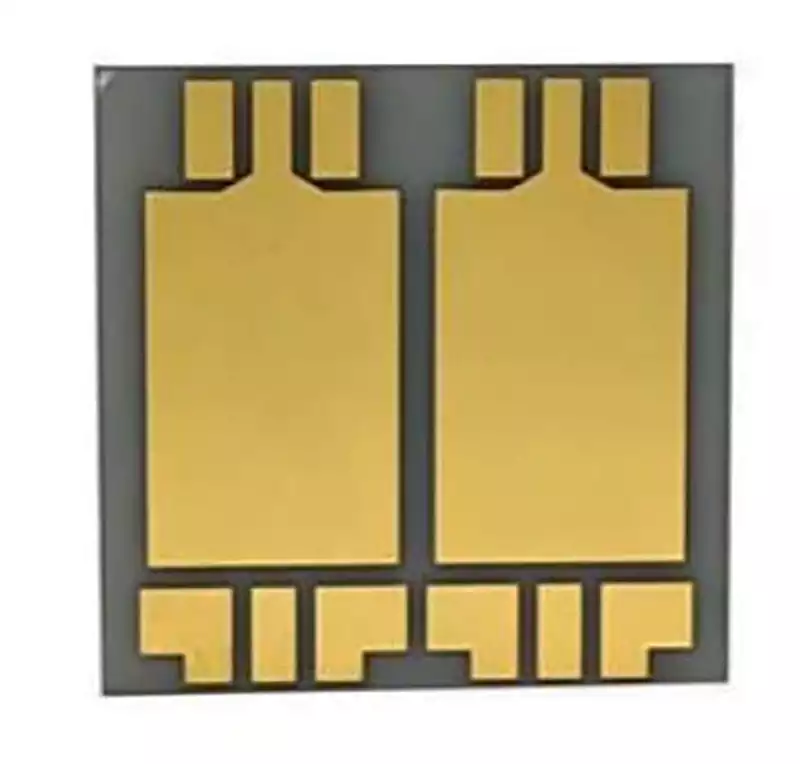

- Surface treatment: Pad electroplating improves solderability, commonly including lead or lead-free HASL and ENIG electroplating. The latter has better oxidation resistance and surface flatness, and is suitable for large BGA components.

- Impedance control: PCBs with wireless functions need to specify impedance control, which is influenced by various factors and is crucial for optimizing wireless antenna performance, which may increase manufacturing costs. 7. Minimum width/spacing: It involves copper wire width and spacing, and failure to meet tolerance standards can cause problems. Copper resources should be utilized reasonably.

- Hole size: The size setting of holes and vias on the circuit board. Although small sizes save space, they are difficult to manufacture, have stricter drilling tolerances, and are prone to waste.

- Solder mask: prevents solder bridges and short circuits, with multiple colors to choose from. It may change color during production and needs to be selected reasonably.

- Screen printing: used to record PCB information, LPI printing can provide higher resolution, but the price is slightly higher.

- Minimum spacing: refers to the distance between adjacent pins of electrical components. If the spacing is too narrow, it will affect production and cost. Specific packaging is more challenging during prototyping or manual assembly

- Tooth shaped hole: Used for installing templates or PCB designs onto other PCBs.

- ROHS compliance: During production, it is necessary to clearly inform the manufacturer of the requirements to avoid mixing non compliant components into the design.

The importance of PCB board prototypes in the manufacturing process:

- Accelerate overall production:

Highly accurate PCB board prototypes help minimize possible iterations and rework during the production phase. Prototype design allows for early detection of defects, providing manufacturers with sufficient time to correct them before actual production. In addition, with prototypes, manufacturers are more likely to communicate with customers and help them understand key design elements. In fact, customers can also request changes or modifications, which can be time-consuming in the later stages of production. - Testing:

The PCB prototyping process is not just a random error detection process. On the other hand, it is a critical step that includes several testing processes, such as temperature change testing, power change testing, impact resistance testing, etc. All of these tests will check the circuit board’s ability to operate in harsh environmental conditions. The designers also carefully inspect all components and their functions to ensure that they work as expected. This small inspection allows for faster and more accurate creation of PCBs in actual production operations.

1) PCB design

Prototype design can help engineers detect defects early in the development process. The more accurate the design, the more prepared the defect identification, which can minimize design costs and shorten project time.

2) Functional testing

There are some things that are effective in theory, but not in practice. Accurate PCB boards can help evaluate theoretical values and check if they appear in actual values. Printed circuit board prototypes can inspect and evaluate some functions of products.

3) Condition testing

Many products need to be applied to special environments, so PCB products must undergo appropriate testing to ensure normal operation in the environment. For example, prototypes typically undergo temperature change testing, power change testing, impact resistance testing, and so on.

4) Final product design

PCB prototypes help determine whether to adjust the product or packaging plan for the final PCB design. For the above purposes, accurate PCB prototypes can greatly simplify other processes and help engineers prepare for production plans.

- Minimize costs:

Early detection of errors helps manufacturers to easily and promptly correct them at the lowest cost. This is not the case when faults are discovered during the production phase. Discovering design flaws in the later stages requires a huge amount of funding to fix them. This will in turn completely affect the project budget and schedule. In addition, PCB board prototype design allows manufacturers to arrange materials and components in advance according to design specifications. They can also find and test cost-effective components, materials, and assembly methods. Overall, prototyping minimizes last-minute rush in material procurement while enabling them to make appropriate decisions on manufacturing methods.

1) Complete testing:

PCB prototypes can help PCB design engineers quickly and accurately test design issues. Without this point, discovering design flaws would require more time, and if not delivered in a timely manner, it could lead to customer dissatisfaction and result in revenue losses.

2) Customers see the product in advance for better communication

Customers usually hope to see the product at multiple points during the production process, and providing prototypes as an aid can help better convey the design. It can also minimize communication with clients and the time required for clients to request redesign.

3) Minimize rework to the greatest extent possible

PCB prototype testing can inspect and test circuit boards before they are put into production, reducing rework. If defective products are put into production, it will take longer and incur more costs in the later stages.

4) Discovering design flaws

The earlier engineers discover design defects, the earlier they can be repaired, and the lower the repair cost. The later the problem is discovered, the higher the repair cost. If the problem persists until full production, it may disrupt the budget. Through high-quality PCB prototyping services, design defects can be quickly and accurately discovered and resolved, which can reduce costs in the long run.

PCB Board Prototype Application

Printed circuit boards that connect components through various related circuits are the core of many different electronic devices we use every day. They have many different variants that enable them to function in various situations. PCB is a component of electronic products used in almost all industries. You can find them in the fields of consumer electronics, medical equipment, automotive parts, industrial equipment, lighting technology, aerospace instruments, and more.

As people continue to innovate and create more new electronic devices, PCBs have become more common. It is precisely in the development of these new products that prototype PCBs are the most useful. If your project involves any of the following situations, you should consider prototyping:

New Product – Whenever your project involves developing a new product, you should use PCB board prototype design. If there is no prototype design, you may not be able to detect any existing issues, which can lead to more serious problems or be more difficult to fix. Even if your project is very similar to one you have successfully completed, prototyping can still be helpful. Many different factors can affect the performance and prototype design of a device, allowing you to quickly and economically identify any factors that need to be adjusted.

Quality and Design Testing – If you want to conduct quality testing or design review, you should order printed circuit board prototypes. A shorter build time will allow you to start reviewing or testing faster and will reduce your overall costs. The PCB prototype will give you an accurate understanding of the performance of the final product. They enable you to validate quality and performance before investing in larger standard production runs, helping you complete projects faster or more cost effectively.

Complex Components – If your project contains multiple PCB based components, PCB board prototypes should be used. More components may mean more functionality, but more potential failures. For these more complex projects, prototyping is particularly useful as it helps to quickly identify which component is not executing correctly. By ordering one PCB at a time, you can spend less time testing and correcting issues and save money.

Modeling purpose – If a physical design is to be presented without the need for circuit board operation, a prototype should be used. In some cases, you may want to have a design model to illustrate how it works. In these cases, you do not need a fully functional circuit board. You only need to accurately represent the design. Using PCB board prototypes for this visual effect is more cost-effective than using standard production boards.