Rogers PCB boards are high-performance, highly reliable printed circuit board materials manufactured by Rogers Corporation. ‘Rogers’ is in fact the brand name of the American company Rogers Corporation. It is an international firm specialising in high-performance materials, renowned globally particularly for its copper-clad laminate materials used in high-frequency, high-speed applications.

Rogers Corporation is a leading manufacturer of high-frequency laminates, offering multiple series of rogers pcb materials, each specifically engineered to meet particular requirements for dielectric constant, loss tangent, and other critical properties. Below are some notable Rogers PCB series and their applicable application areas:

RO3000 Series: Renowned for high-frequency performance and low loss, the RO3000 utilises a ceramic-filled polytetrafluoroethylene composite with a primary matrix of glass-braided and nylon. Operating within the 50 GHz frequency range, it is suitable for commercial microwave and RF applications. Featuring a low loss tangent, it is ideal for applications requiring low insertion loss, such as patch antennas, power amplifiers, and other high-frequency systems.

Rogers RO4000 Series: Introduced as the first low-loss high-frequency material, the RO4000 is based on a polyester substrate. Operating within the 18 GHz frequency range, it is highly suitable for RF power amplifiers, cellular base station antennas, and direct broadcast satellite low-noise amplifiers.

Rogers TMM Series: The TMM series thermoset microwave laminates combine high thermal conductivity, low coefficient of thermal expansion (CTE), and rigid mechanical properties. With an operating temperature range of -55°C to 260°C, it is well-suited for heat sinks or mounting surfaces in power amplifiers or oscillators.

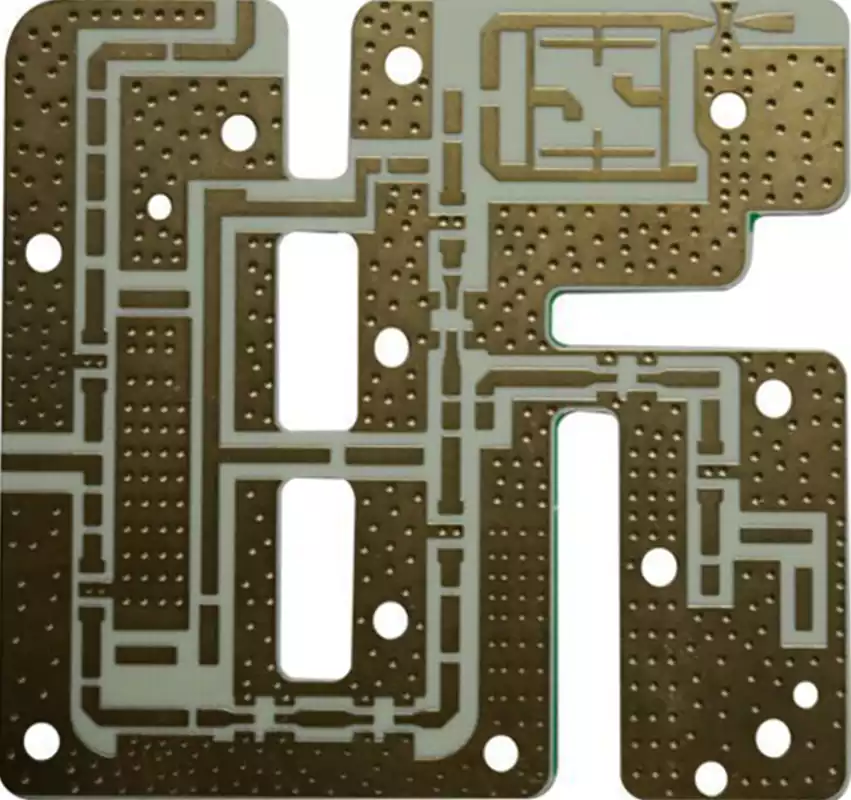

Rogers RT/duroid Series: Comprising primarily PTFE and utilising reverse-processed PTFE technology, this series of high-frequency laminates delivers outstanding electrical and mechanical stability. Operating beyond 110 GHz, it serves military radar systems, broadband wireless networks, and complex multilayer boards and microwave circuits demanding superior thermal conductivity and high power handling.

Rogers AD Series: Engineered for high-frequency integrated circuit applications such as 5G communications and radar chipset solutions, these materials deliver outstanding performance in safety-critical radar sensors.

Rogers ULTRALAM 2000 Series: Operating up to 40 GHz with a temperature range of -55°C to 260°C, the ULTRALAM 2000 Series maintains stable dielectric constant characteristics across its frequency range. It is suitable for microwave communication systems, radar technology, electromagnetic interference systems, industrial applications, and communication networks.

Characteristics of Rogers PCB:

Electrical Performance Advantages

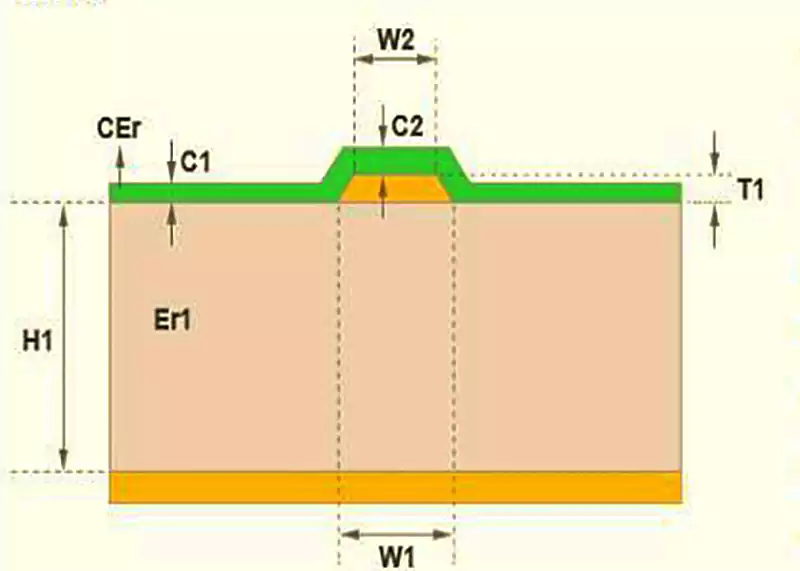

Low Dielectric Constant and Low Loss Properties: Rogers laminates exhibit stable and low dielectric constants, typically ranging between 2.2 and 10.2.For certain products within the RO4000 series, the dielectric constant generally falls between 3.55 and 4.2. Concurrently, these laminates exhibit exceptionally low loss factors,with RO4835 achieving values as low as 0.0035. This characteristic substantially reduces signal transmission losses in high-frequency circuits, robustly safeguarding signal integrity and precision. It effectively mitigates signal distortion and attenuation issues, thereby enhancing transmission quality and efficiency.

Stability in High-Frequency Environments: Within high-frequency operational scenarios, Rogers laminates exhibit remarkably stable electrical properties. Their dielectric constant and loss factor remain relatively constant without significant variation as frequency increases. This ensures stable operation of high-frequency circuits across diverse frequency conditions, establishing a robust foundation for high-speed, reliable signal transmission.

Low Electromagnetic Interference and High Electromagnetic Compatibility: Rogers laminates possess outstanding electromagnetic shielding properties, effectively suppressing the generation and propagation of electromagnetic interference. This reduces mutual interference between circuits and significantly enhances the electromagnetic compatibility of the system. In high-frequency circuits, where component layout is dense and signal transmission complex, this characteristic is particularly crucial, contributing to improved circuit reliability and stability.

Thermal Performance Advantages

Exceptional Thermal Stability: Rogers laminates typically exhibit a glass transition temperature (Tg) exceeding 280°C, demonstrating outstanding thermal stability. During operation, high-frequency circuits generate heat due to current flow and signal transmission. These laminates maintain stable performance under elevated temperatures, preventing thermal deformation or failure that could disrupt circuit functionality. This enhances circuit reliability and extends service life.

Low Thermal Expansion Coefficient: Rogers laminates exhibit thermal expansion coefficients compatible with common metals and semiconductor materials, showing minimal deviation from copper’s coefficient. In high-frequency circuits, thermal stress may arise from differing thermal expansion coefficients between materials, compromising circuit performance and reliability. Rogers laminates’ low thermal expansion coefficient effectively minimises thermal stress, preventing issues such as trace fractures and solder joint failures caused by thermal expansion mismatch.

Processing Performance Advantages

Meeting High-Precision Machining Requirements: Rogers laminates demonstrate excellent thickness tolerance control and high surface flatness, fully meeting the demands of high-precision machining. High-frequency circuits often require intricate circuit patterns and minute via structures. This laminate is well-suited to advanced processing techniques such as laser drilling and micro-pattern photolithography, ensuring consistency in circuit machining precision and performance.

Superior Solderability and Laminating Properties: Rogers laminates exhibit strong bonding strength with metallic conductors and excellent solderability, guaranteeing reliable solder joints and circuit connections. During multilayer board lamination, the material bonds tightly with other layer materials, forming stable multilayer structures that enhance overall board performance and mechanical strength.

Application Areas for Rogers PCB Materials:

- Automotive Radar (77 GHz): Rogers’ RO3003 and RO3003G2 ceramic-filled PTFE laminates are the preferred materials for 77 GHz (76 to 81 GHz) radar antennas due to their exceptionally low insertion loss and a stable low dielectric constant over time and temperature.

- 24 GHz automotive radar sensors: RO4835 laminates deliver superior electrical performance and consistency for 24 GHz automotive radar antennas, offering tenfold improved oxidation resistance compared to traditional thermoset materials alongside stable low-loss characteristics.

- 5G wireless infrastructure (millimetre wave): Rogers’ high-frequency circuit materials meet the performance requirements for both external and concealed vehicle communication antennas, including Global Navigation Satellite System (GNSS), Shared Domain Automotive Radar (SDAR), cellular, and V2X antennas. These materials are suitable for high-frequency applications in 5G communications, capable of handling wider bandwidths and higher frequencies.

- Microwave and Millimetre-wave Frequencies: The RO4000 series leads the industry for microwave and millimetre-wave frequencies. This low-loss material offers enhanced ease of use in circuit fabrication and superior performance compared to traditional PTFE materials.

- High-Performance Circuit Materials: Rogers’ high-performance circuit materials provide automotive applications with a comprehensive range of PCB power electronics materials, RF and millimetre-wave PCB laminates. Supported by global technical assistance and worldwide manufacturing sites, these materials enable automotive electronics designers to rapidly enter the fast lane for Advanced Driver Assistance Systems (ADAS) safety and Vehicle-to-Everything (V2X) communication systems.

- Telecommunications: Rogers’ high-frequency PCB laminates are also extensively utilised in telecommunications for base station antennas and power amplifiers, alongside digital applications such as high-speed backplanes.

- Satellite Communications: RO4000 series materials are also suitable for satellite communication equipment such as low-noise blocks (LNBs) for direct broadcast satellites.

- Radio Frequency Identification (RFID) Tags: RO4000 series materials are equally applicable to RFID tags, which are increasingly vital in supply chain management and secure access control.

Rogers PCB materials, leveraging their extensive product portfolio and exceptional performance advantages, excel in critical domains including precise automotive radar detection, high-speed 5G communication transmission, and stable satellite link connectivity. Their reliable quality injects robust momentum into current technological advancements, while also serving as a solid foundation for future complex and diverse innovative applications.