The solder mask serves as an indispensable protective layer on the surface of FR4 PCBs, providing not only a defined aesthetic colour but also fulfilling critical functions such as insulation, preventing solder bridging, and safeguarding copper foil. Faced with diverse colours such as red, blue, green, and black, electronic equipment designers and specifiers often question whether these choices impact core PCB performance. Some perceive colour as purely cosmetic, overlooking the subtle performance implications stemming from underlying material formulation differences. In reality, selecting the appropriate solder resist colour is crucial for balancing aesthetics and functionality across various aspects, from high-frequency signal transmission to thermal dissipation.

The Core Function of the Solder Mask

The solder mask is an insulating coating printed onto the copper foil surface of FR4 PCBs. Its core purpose is not merely decorative, but rather to ensure the reliability and manufacturability of the circuit board. This can be summarised into four primary functions: Firstly, insulation protection, isolating adjacent copper foil traces to prevent short-circuit faults caused by dust or moisture; Secondly, it prevents solder bridging during wave soldering and reflow processes, restricting solder flow to designated areas and ensuring precise joint formation. Thirdly, it shields copper traces from oxidation and corrosion, extending the PCB’s operational lifespan. Fourthly, it enhances mechanical protection by reducing damage to surface traces from friction or impact.

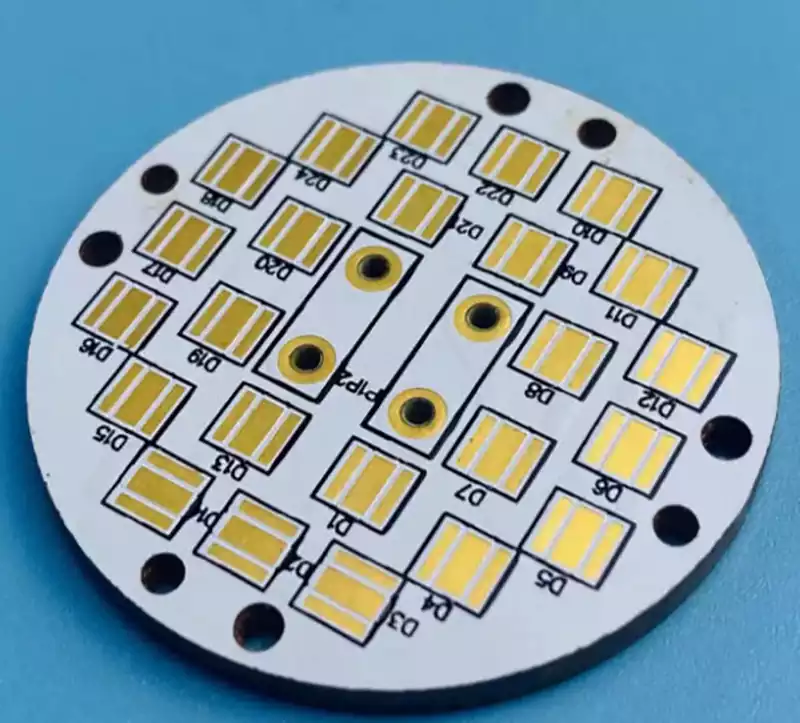

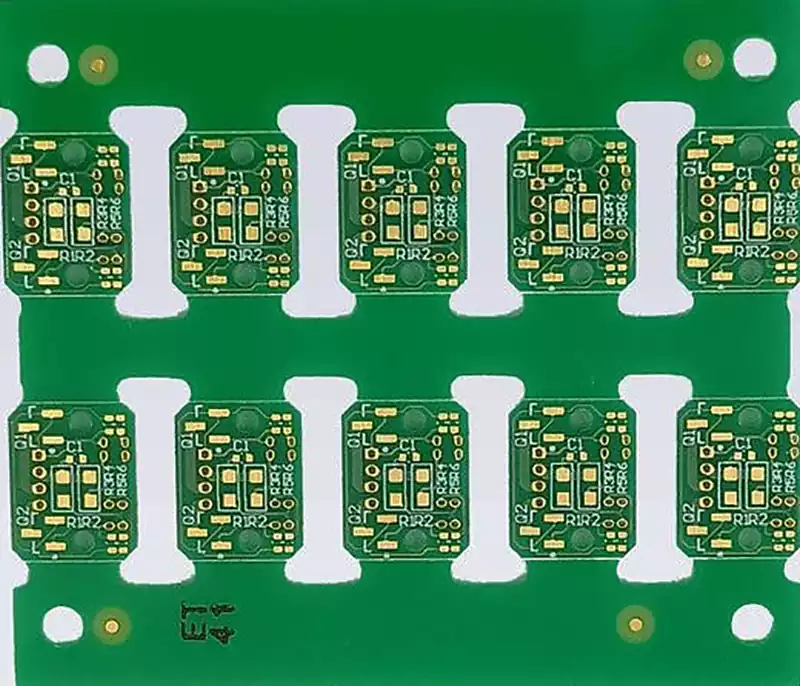

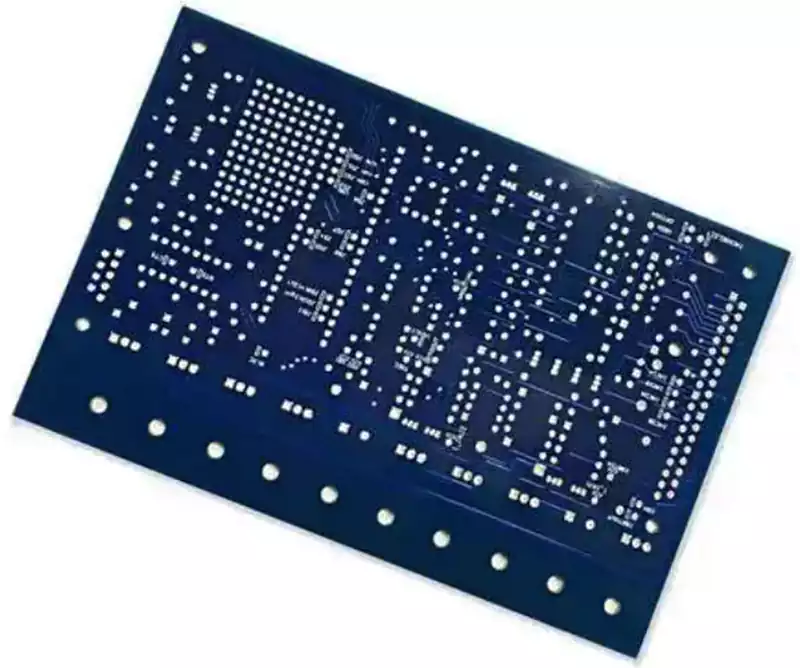

The formation of solder resist colours stems from the addition of colour paste components within the solder resist ink. Formulations for different colours vary, with the material composition and addition ratio of the colour paste being key variables influencing FR4 PCB performance. Among conventional solder resist colours, green dominates the industry (accounting for over 80%), followed by black, red, blue, yellow, and others. Green’s dominance stems not from superior performance, but from its lower paste cost, mature manufacturing process, and optimal contrast during AOI inspection, facilitating defect detection during production. Other colours serve differentiation needs: black aligns with premium electronic device aesthetics, while red and blue distinguish functional modules on circuit boards.

The Impact of Soldermask Colour on FR4 PCB Performance

1.Dielectric Properties

Dielectric properties (dielectric constant Dk, dielectric loss Df) are core indicators affecting high-frequency signal transmission in FR4 PCBs. As the surface coating layer, solder mask ink’s dielectric properties directly influence signal transmission quality. Differences in dielectric properties between coloured solder resist primarily stem from pigment composition—inorganic pigments (e.g., titanium dioxide, carbon black) exhibit markedly distinct dielectric characteristics compared to organic pigments.

Green, blue, and red solder resist inks predominantly utilise inorganic oxide pigments (e.g., chrome green for green, cobalt blue for blue). Such pigments typically exhibit dielectric constants ranging from 3.0 to 3.8, with dielectric loss below 0.02. This compatibility with the dielectric properties of the FR4 substrate (Dk 4.2–4.8, Df < 0.02), thus causing no significant interference to high-frequency signal transmission. Conversely, black soldermask inks predominantly employ carbon black paste. As a conductive filler, carbon black elevates the dielectric constant (potentially reaching 4.0–4.5) and increases dielectric loss (with some products exhibiting Df > 0.03) even at low addition ratios. In high-frequency applications (e.g., 5G millimetre-wave, high-speed serial buses), black soldermask exacerbates signal attenuation and crosstalk, compromising transmission rates and signal integrity. Experimental data indicates that at 25GHz, FR4 PCBs with black soldermask exhibit 15%-20% greater signal attenuation than those with green soldermask.

2.Thermal Performance

The thermal efficiency of FR4 PCBs primarily relies on the thermal conductivity of the substrate material and copper foil. As a surface coating, the solder mask’s thermal performance manifests in its thermal radiation and heat absorption capabilities, which are directly linked to the optical properties of its colour—light-coloured solder resist exhibit high reflectivity and low absorptivity, while dark-coloured ones demonstrate the opposite characteristics.

In scenarios involving natural convection or forced air cooling, light-coloured soldermasks (white, yellow, light green) demonstrate a clear thermal advantage. White solder resist exhibits the lowest solar absorption rate (approximately 0.2–0.3) and the highest thermal emissivity (approximately 0.8–0.9), effectively reflecting external heat while radiating heat generated internally within the PCB. Conversely, black solder resist exhibits solar absorption rates as high as 0.8–0.9, causing substantial absorption of external heat and elevated PCB surface temperatures. Experimental data indicates that under identical power load and ambient conditions, FR4 PCBs with black solder mask exhibit surface temperatures 8–12°C higher than those with white soldermask. However, within enclosed, light-free equipment (such as server enclosures or industrial control modules), the absence of external illumination significantly reduces the impact of solder resist colour on heat dissipation. Under these conditions, thermal efficiency is primarily determined by the substrate material and copper foil layout, with temperature differences between solder resist of varying colours narrowing to within 2°C.

3.Environmental Resistance

The environmental resistance of FR4 PCBs (resistance to humidity, heat, ultraviolet radiation, and chemical corrosion) is closely related to the base resin of the solder resist ink, the curing process, and the stability of the colour paste. Differences in environmental resistance between solder resists of different colours primarily stem from the ageing resistance of the colour paste.

Green soldermask pastes (e.g., chrome green) exhibit strong chemical stability, excellent UV ageing resistance, and superior moisture-heat performance. After 1000 hours of moisture-heat ageing (85°C/85% RH), their insulation resistance degradation rate remains below 10%, with no fading or cracking observed. Red and blue soldermask pastes (e.g., azo red, phthalocyanine blue) exhibit weaker UV resistance, prone to fading under prolonged outdoor exposure. Their moisture and heat resistance is also marginally inferior to green paste, potentially leading to coating blistering after ageing. Black soldermask carbon black pastes exhibit superior UV resistance. However, some low-cost black inks utilise inferior resins, resulting in inadequate chemical corrosion resistance. Exposure to flux, cleaners, and other chemicals may cause coating detachment. Furthermore, yellow soldermask inks demonstrate the poorest lightfastness, tending to yellow under prolonged illumination. This not only compromises visual identification but may also be accompanied by a decline in insulation performance.

4.Manufacturability and Testability

The colour of solder resist affects the production efficiency and quality inspection of FR4 PCBs. While this impact does not directly affect the functional performance of the circuit board, it influences production yield and costs.

Green solder mask remains the industry standard, offering moderate contrast against copper foil and pads. During AOI (Automated Optical Inspection), it enables clear differentiation between traces, pads, and mask areas, facilitating the detection of defects such as short circuits, open circuits, and mask misalignment. AOI inspection yields can exceed 95%. Black solder mask exhibits extremely low contrast with copper foil, making it difficult to identify minute defects (such as micro-short circuits or solder mask bubbles) during AOI inspection. This results in a higher miss rate, typically necessitating supplementary X-ray inspection and increasing production costs. Whilst white and yellow solder masks offer high contrast with pads, they reduce the clarity of screen-printed characters (often black), impacting subsequent manual repairs and component placement during soldering. Furthermore, green solder mask inks possess the most mature curing processes, compatible with most PCB production lines. Conversely, curing parameters for certain special colours (e.g., fluorescent or custom shades) require individual calibration, resulting in longer production cycles and higher costs.

Strategies for Solder Mask Colour Selection Based on Different Requirements

1.High-Frequency, High-Speed Applications (5G, High-Speed Computing, Millimetre-Wave Devices)

Core Requirements: Low dielectric loss, low signal attenuation.

Selection recommendation: Prioritise green or blue solder resist; avoid black solder resist. For differentiated aesthetics, consider red solder masks using high-purity inorganic colour pastes, ensuring dielectric loss Df < 0.025. Additionally, select low-loss solder mask inks (e.g., modified epoxy resin systems) to further mitigate impact on high-frequency signals.

2.Outdoor High-Temperature Environments (Automotive Electronics, Outdoor Communication Equipment, PV Inverters)

Core Requirements: Effective heat dissipation, resistance to UV ageing.

Selection Recommendations: Prioritise white or light grey solder resist for their high reflectivity to reduce surface temperatures. Where both aesthetics and weather resistance are required, opt for high-quality green solder resist (using weather-resistant colour pastes). Avoid black or dark brown solder masks to prevent internal overheating caused by heat absorption.

3.Enclosed equipment interiors (servers, industrial control modules, medical devices)

Core requirements: Resistance to humid heat, high reliability, ease of inspection.

Selection recommendations: Prioritise green solder mask for balanced manufacturing yield and environmental resistance. To differentiate functional modules, combine green with blue or red (assign distinct colours to separate modules within the same device) – this facilitates assembly and maintenance without compromising performance. Black solder mask may be used in medical devices or servers requiring premium aesthetics, but select low-loss carbon black paste solder mask inks.

4.Consumer Electronics Applications (Smartphones, Wearables, Smart Home Devices)

Core Requirements: Aesthetic appeal, compact size, low cost.

Selection Recommendations: Colour selection may align with brand identity (e.g., black for premium smartphones, colourful options for smart home devices), but avoid black solder mask on high-frequency modules (e.g., mobile phone RF sections). Additionally, opt for thin solder mask inks (20-30μm thickness) to minimise impact on device dimensions while balancing thermal dissipation and aesthetics.

FAQ

Q1: Is green solder mask the optimal choice for FR4 PCBs?

A1: Not absolutely optimal, but it represents the ‘most versatile’ option. Green solder mask offers balanced dielectric properties and environmental resistance, with mature manufacturing processes, lower costs, and good compatibility with AOI inspection. It meets most requirements for low-to-medium frequency and standard environmental applications. However, in special scenarios like high-frequency or outdoor high-temperature environments, lighter colours or low-loss alternative solder mask colours may be necessary.

Q2: Does black solder mask inevitably impair the high-frequency performance of FR4 PCBs?

A2: Not necessarily; it critically depends on the solder mask ink formulation. High-quality black inks using low-conductivity carbon black paste and modified epoxy resin systems can control dielectric loss below 0.025, causing minimal signal impact below 10GHz. However, at frequencies above 25GHz, even premium black solder masks exhibit more pronounced signal attenuation than green variants and are not recommended.

Q3: Does the colour of solder mask significantly affect the insulation properties of FR4 PCBs?

A3: Under normal circumstances, the impact is minimal, as insulation properties are primarily determined by the resin base material of the solder mask ink. However, inferior colour pastes may compromise insulation performance. For instance, certain low-cost red or yellow solder mask inks contain colour pastes prone to water absorption, which can lead to reduced insulation resistance in prolonged humid and hot environments. Black solder mask with uneven carbon black dispersion may create local conductive pathways, posing insulation risks. Selecting reputable brands of solder mask inks compliant with IPC-6012 standards mitigates this issue.

Q4: Must outdoor-use FR4 PCBs employ light-coloured solder mask?

A4: Not strictly necessary, but light-coloured soldermasks enhance heat dissipation efficiency and extend equipment lifespan. For outdoor devices employing forced cooling (e.g., fans, heat sinks) with low PCB power density, green soldermasks may suffice. However, for high-power-density equipment relying on natural cooling, white or light grey solder masks are recommended to prevent excessive temperatures associated with black variants.

Q5: Is there a significant cost difference between soldermask colours?

A5: There is a difference. Green soldermask is the most economical, while special colours incur higher costs. Green soldermask ink enjoys high market penetration with mature raw materials and production processes, costing approximately ¥0.8–1.2 per square metre. Black, red, and blue solder masks are 20–50% more expensive than green. Special colours like white or fluorescent hues are significantly pricier—roughly 2–3 times the cost of green—and require longer production lead times.

Q6: Does soldermask colour affect the mechanical strength of FR4 PCBs?

A6: Essentially no impact. The mechanical strength of FR4 PCBs is primarily determined by the substrate (glass fibre cloth + epoxy resin), board thickness, and copper foil coverage. The solder mask layer is only 20-50μm thick and is a flexible coating, rendering its effect on overall mechanical strength (bending resistance, tensile strength) negligible. The hardness difference between soldermasks of different colours is minimal, and all can meet standard mechanical protection requirements.