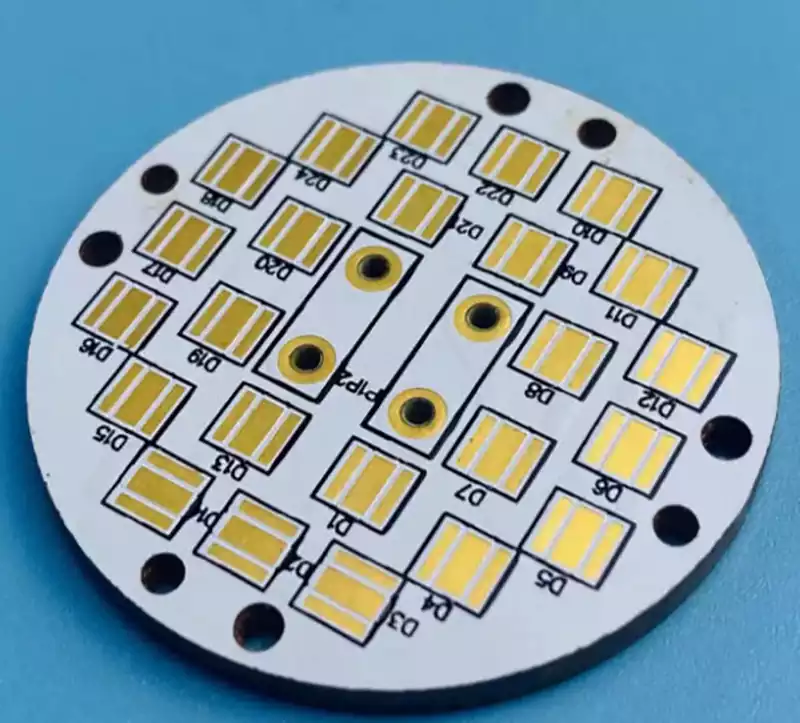

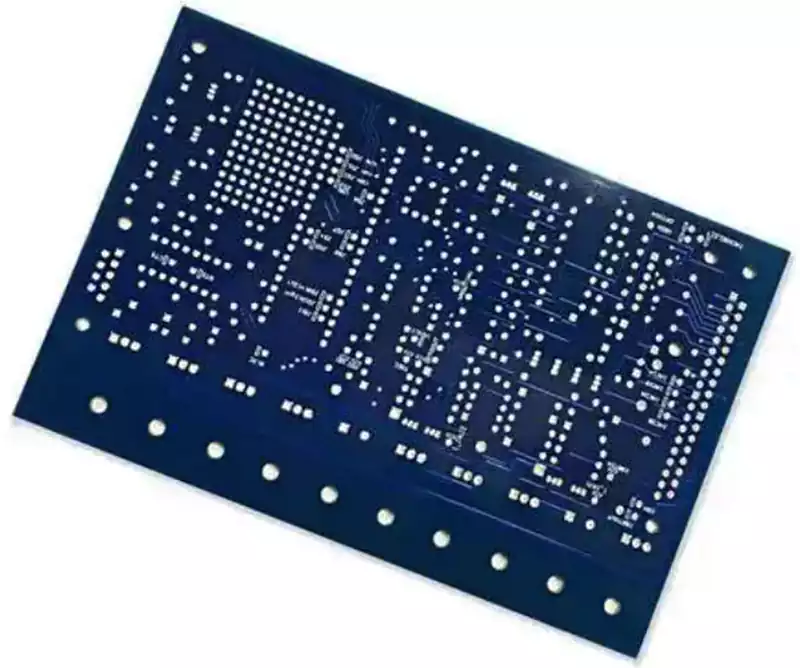

What is FR4? FR4 is a grade of material used as a standard in PCB (printed circuit board) manufacturing. The term ‘FR4’ actually refers to a specific type of glass fibre reinforced epoxy laminate. It is produced by laminating a fabric made from glass fibres (which provides the material’s strength) with epoxy resin (which binds all the parts together). ‘FR’ stands for ‘Flame Retardant’, meaning this material possesses flame-retardant properties, making it safer for electrical and electronic applications.

This composite material is commonly used as the base material for circuit boards and finds widespread application across various fields, ranging from household appliances to automotive electronics and even aerospace technology.

Key Characteristics

Strength and Durability

FR4 is renowned for its strength and durability. The layers of glass fibre embedded within the resin provide exceptional mechanical strength, making it an ideal material for PCBs subjected to physical stress. Its resistance to bending and cracking renders it highly favoured in applications requiring long-term reliable performance.

Flame Retardancy

Composed of epoxy resin and glass fibre composite, the ‘FR’ in FR4 denotes ‘flame retardant’. During production, FR4 undergoes specialised treatment incorporating flame retardants, endowing it with superior fire-resistant properties. This renders it invaluable in fire and explosion prevention within electronic equipment. In environments with fire hazards, employing flame-retardant materials like FR4 effectively mitigates the risk of electrical fires. The materials typically comply with the international standard UL94 V-0, one of the common flame retardant rating standards for electronic products. V-0 rated materials indicate that the material will not drip burning material during combustion and will self-extinguish within 5 seconds after the ignition source is removed.

Excellent Electrical Insulation

It also possesses outstanding electrical insulation properties, which are crucial for preventing short circuits and ensuring the proper functioning of electronic components. It effectively isolates electrical pathways from the surrounding environment, minimising the risk of accidental contact.

Thermal Stability

FR4 material exhibits relatively high heat resistance, meaning it can perform well in high-temperature environments. In electronic products, thermal management is vital for maintaining component longevity and performance. FR4 also withstands thermal cycling, making it suitable for equipment requiring frequent heating and cooling.

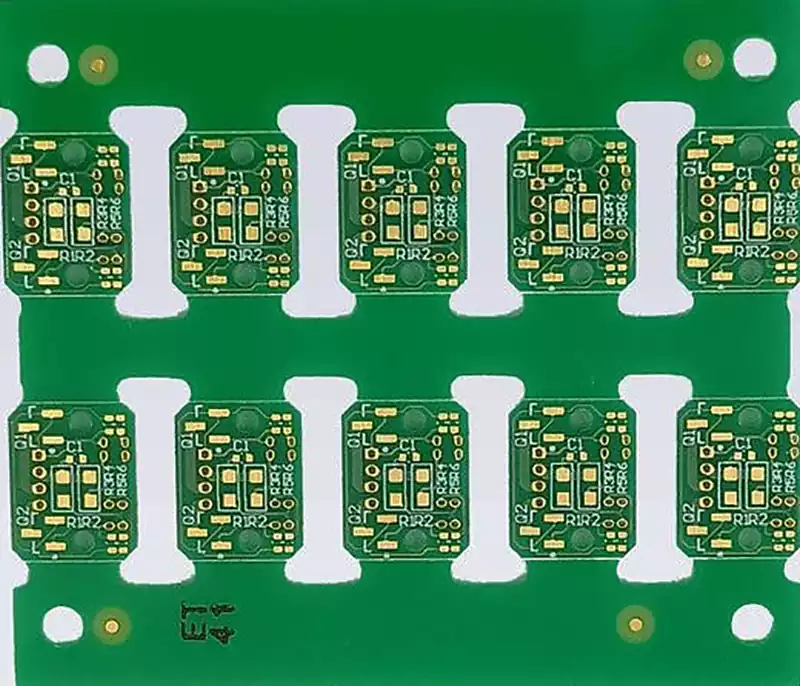

Versatility

A major advantage of FR4 is its versatility. It can be utilised across diverse applications and is widely employed in various industries, ranging from communications and automotive to medical devices and consumer electronics. Its adaptability makes it the material of choice for numerous electronic projects.

Advantages

Cost-Effectiveness

A key reason for FR4’s widespread adoption lies in its cost-effectiveness. Whilst other materials may offer superior performance in certain aspects, FR4 strikes an excellent balance between price and functionality. This renders it highly accessible for both small manufacturers and large-scale industrial applications.

Ease of Fabrication

It is relatively straightforward to process and manufacture, making it a staple material within the PCB industry. It can be readily cut, drilled, and moulded into required shapes, thereby streamlining production processes and reducing lead times.

Reliability

It has been tested and proven reliable across numerous applications. Its well-established properties, including flame retardancy, strength, and insulation, make it a dependable material for critical applications where equipment failure could lead to costly consequences or hazardous outcomes.

Limitations

While FR4 offers many benefits, it is not without its limitations. For example, it can be brittle in certain applications, and its heat resistance, while adequate, may not be enough for extremely high-temperature environments. In cases where higher thermal performance is required, materials like polyimide (used in flexible PCBs) or ceramic may be considered.

Additionally, FR4 does not perform well under conditions that require high-speed signal transmission because of its dielectric properties, which may cause signal degradation.

FR4 is a vital material in the world of electronics, particularly for its use in printed circuit boards. Its flame-retardant properties, strength, electrical insulation, and cost-effectiveness make it an essential part of countless electronic devices across a wide range of industries. While it has some limitations, its versatility and reliability continue to make it a top choice for manufacturers. Whether you’re building a smartphone, an electric vehicle, or a medical device, chances are, you’re relying on FR4 to ensure your circuit boards perform to the highest standards.