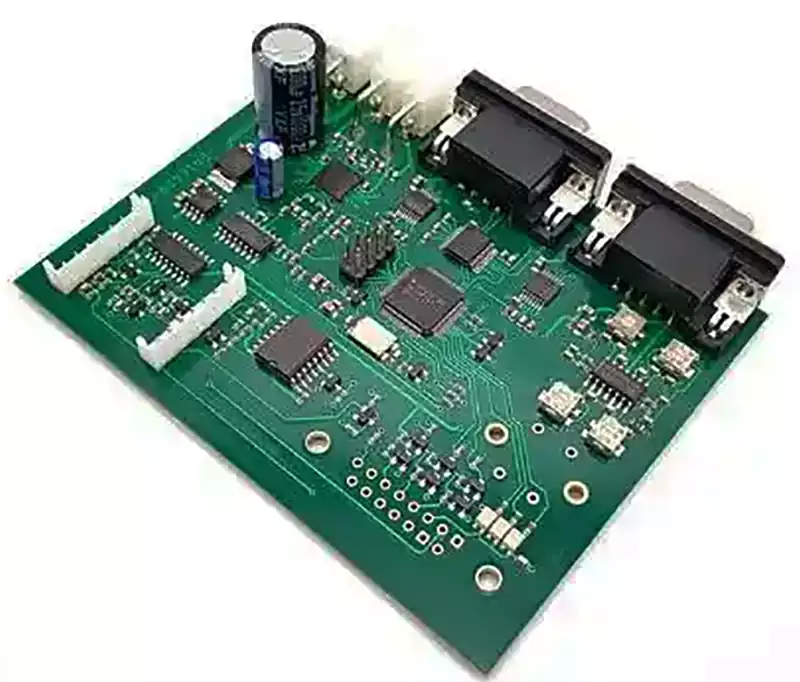

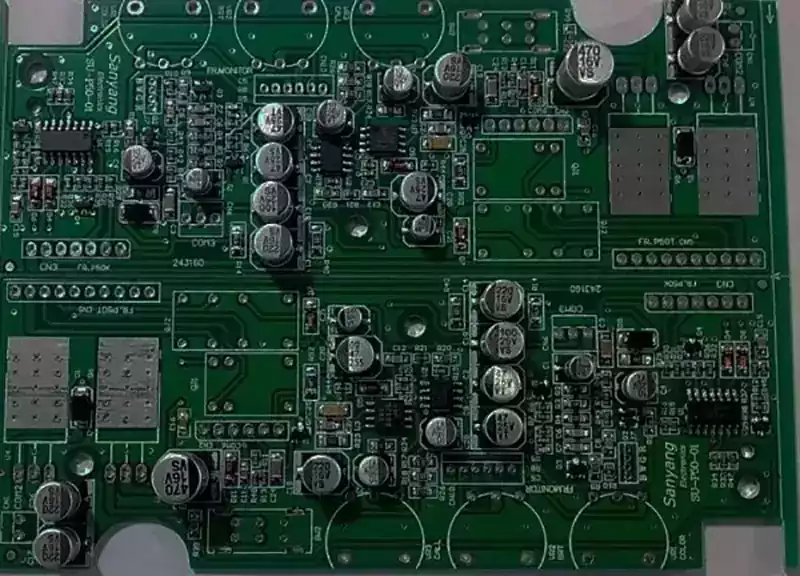

What is PCBA? PCBA meaning pcb board assembly, which refers to the printed circuit board that has already been installed with various electronic components and is further processed on the basis of the PCB. Simply put, PCB+electronic components=PCBA. PCB is an empty board, while PCB assembly is a circuit board that has completed all component assembly and can be directly used in electronic products.

PCB board assembly is a semi-finished circuit board, including the board and the accessories attached to it. PCB is the abbreviation for printed circuit board, which comes in different materials and processes. SMT is a manufacturing process that involves specialized machines producing circuit boards using machine supported components, typically without pins. That is to say, the blank pcb board undergoes the entire process of SMT mounting or DIP plug-in, abbreviated as PCBA.

SMT and DIP are both ways of integrating parts on a PCB board, with the main difference being that SMT does not require drilling holes on the PCB circuit board, while DIP requires inserting the PIN pins of the parts into the already drilled holes.

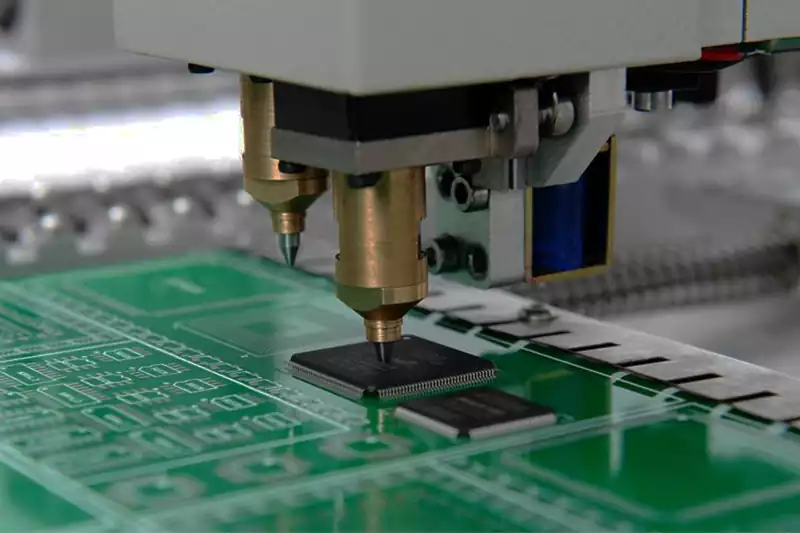

SMT (Surface Mounted Technology) is a surface mount technology that mainly uses a mounting machine to mount some small parts onto a PCB board. Its production process includes printed wiring board positioning, printing solder paste, mounting by the mounting machine, passing through a reflow oven, and manufacturing inspection. SMT integration is sensitive to positioning and part size, and the quality of solder paste and printing also play a key role.

DIP stands for “plug-in”, which means inserting parts onto a PCB board. Due to the large size of the parts and their unsuitability for mounting or when SMT technology cannot be used in the manufacturer’s production process, plug-in is used to integrate the parts. At present, there are two implementation methods for manual plugins and robot plugins in the industry, and their main production processes are: adhesive bonding (to prevent tin plating from reaching inappropriate places), plugin, inspection, wave soldering, plate brushing (to remove stains left during the furnace process), and manufacturing inspection.

Core technical characteristics of PCBA

1.Electrical performance characteristics

Signal integrity: In high-frequency circuits, PCB assembly needs to ensure the integrity of signal transmission by controlling characteristic impedance (50 Ω/75 Ω), suppressing reflection crosstalk, and achieving low loss signal transmission.

Power integrity: Through multi-layer PCB design and decoupling capacitor optimization, voltage fluctuations are controlled to be ≤ ± 5%, ensuring stable power supply to chips and other electronic components.

2.Mechanical and physical properties

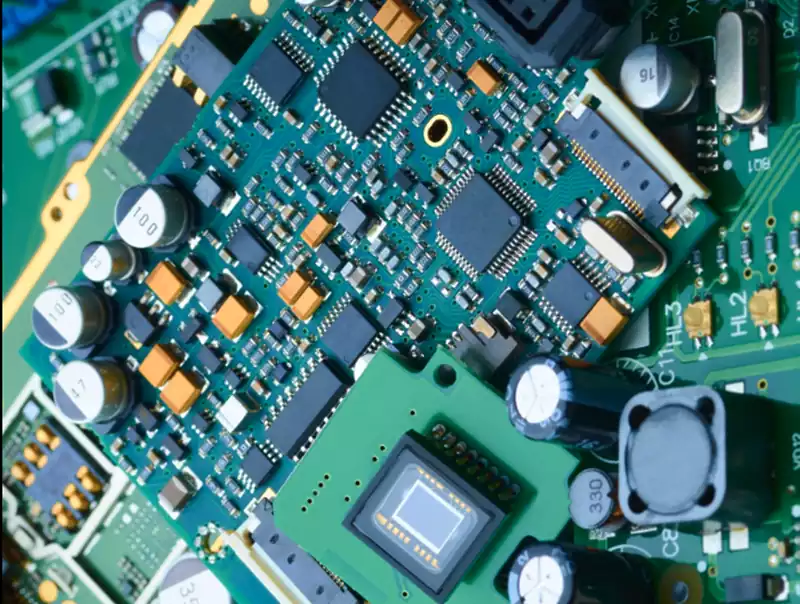

High density integration: With the trend of miniaturization of electronic products, PCB board assembly needs to have extremely high integration and precision to meet various needs of modern electronic products.

Heat dissipation performance: For high-power devices, PCB assembly needs to have good heat dissipation capability.

3.Process reliability characteristics

Welding reliability: Welding quality directly affects the service life of printed circuirt board assembly. SMT and wave soldering are the main welding processes, and it is necessary to strictly control parameters such as welding temperature curve and solder paste composition.

Environmental adaptability: Depending on different application scenarios, PCB assembly needs to meet specific environmental requirements (e.g. military industry)

4.Manufacturability and testability

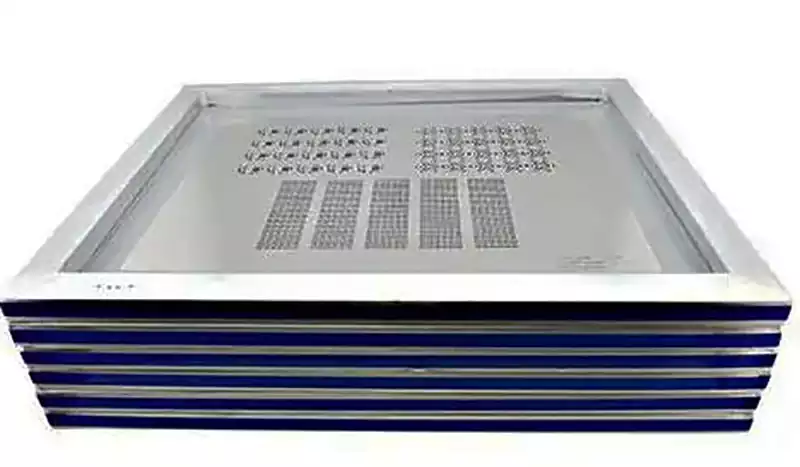

Manufacturability (DFM): In the design phase, the feasibility of the production process needs to be considered, including the rationality of component layout, steel mesh opening design, etc., to reduce the defect rate in the production process.

Testability (DFT): By setting up test points and utilizing technologies such as JTAG, it facilitates ICT (online testing) and FCT (functional testing) during the production process to ensure the proper functioning of the PCB board assembly.

Electronic components, as the core components of PCBA board, can be divided into the following three categories based on their functional characteristics and installation processes:

1.Plug in components (THT components)

This type of component is electrically connected by inserting metal pins into through holes on the PCB board, and typical representatives include axial resistors, electrolytic capacitors, and color ring inductors. Its physical size is relatively large, with stronger current carrying capacity (usually up to several amperes) and withstand voltage characteristics (up to thousands of volts), making it widely used in power modules, industrial control equipment, and other scenarios that require strict electrical performance.

2.Surface mount devices (SMD components)

Micro components fixed on the surface of PCB using reflow soldering technology, including SOT (small form factor transistor), SOP (small form factor package), QFP (four pin flat package) and other IC chips, as well as 0402/0603 size chip resistors and capacitors. These types of components are compact in size (with a minimum package size of up to 0.3 × 0.15mm), lightweight, and support double-sided mounting design, making them particularly suitable for high-density integrated electronic products such as smartphones and wearable devices.

3.Ball Grid Array Devices (BGA Components)

A high-end component that achieves flip chip bonding between solder balls (diameter 0.2-0.76mm) distributed in the bottom array and PCB, mainly used in core processors such as CPU, GPU, FPGA, etc. Its pin density is extremely high (up to 2000+pins per chip), which imposes strict requirements on the soldering process: X-ray inspection is required to verify the integrity of solder joints, and high-precision surface mount machines (repeat positioning accuracy ± 0.02mm) and vacuum reflow soldering furnaces (temperature uniformity ± 3 ℃) are used to ensure soldering reliability.

PCBA manufacturing process:

1.PCB design: The PCB design process requires the use of EDA tools (such as Altium Designer, KiCad, etc.) to complete circuit schematic drawing and pwb board spatial layout planning, accurately determining the installation coordinates of each electronic component, electrical wiring specifications, and multi-layer board stacking structure. As a fundamental step in the PCBA manufacturing process, this stage is equivalent to the blueprint design of a construction project, and its design quality and detail accuracy will directly determine the engineering feasibility of subsequent component mounting, signal integrity verification, and overall reliability testing.

2.Component procurement: Implement electronic component procurement operations based on design documents (BOM list), strictly check key indicators such as device parameters, specifications, model codes, and quality levels, and ensure that the technical characteristics of all materials fully match the design requirements, providing a standardized component foundation for subsequent PCBA manufacturing.

3.SMT surface mount:

-Solder Paste Printing: Printing solder paste onto the solder pads of a PCB board through a steel mesh to prepare for the soldering of subsequent components.

-SMT: Using a SMT machine to accurately mount components onto PCB circuit boards, the SMT machine is like a precise robot that can quickly and accurately mount them Accurately place small components in designated positions.

-Reflow soldering: By heating at high temperature to melt the solder paste, the components are firmly fixed on the pwb to complete the electrical connection.

4.THT plugin (for some components that cannot be installed through SMT process): using through-hole insertion technology (THT), such as large capacitors Connectors and other components are usually soldered using wave soldering or manual soldering. During wave soldering, the circuit board passes through the molten solder waves to complete the soldering of components; Manual welding is suitable for some special situations or small-scale production.

5.Testing and Inspection:

-AOI detection: Automatic optical detection technology uses optical imaging systems to detect the welding condition and component installation position on PCB circuit boards, and can quickly identify obvious welding defects and abnormal situations such as component placement deviations.

-ICT testing: Online testing verifies circuit functionality and checks whether the electrical performance of various components on the circuit board is normal.

-Functional testing: Simulate the actual usage environment to comprehensively test the overall performance of PCBA, ensuring its stable operation in practical applications.

6.Cleaning and protection:

Clean the residual flux and pollutants during the soldering process, and then apply a three proof paint (moisture-proof, dust-proof, and corrosion-resistant) to improve the reliability and service life of the printed circuit board assembly.

7.Packaging and delivery:

Using materials with anti-static function to package printed circuit board assembly, and then transferring the fully packaged finished product to the customer’s designated location or arranging for it to enter the subsequent assembly production process, in order to ensure that the product is protected from electrostatic and other potential factors during transportation and storage.

How to choose a suitable PCBA one-stop supply manufacturer?

1.Check if the PCBA processing manufacturer can truly meet the sampling requirements

Check whether the products manufactured by the manufacturer are high-end, mid-range or low-end, which field of products are manufactured, and whether the manufacturer can provide their own circuit board assembly sampling requirements. Some high-precision PCBA processing companies are often unable to provide such services due to technical capabilities and equipment limitations. If the manufacturer can provide it, it also depends on whether the delivery time of the manufacturer is fast enough! Many PCBA sampling requirements place great emphasis on short delivery times, as the faster the product is, the faster it can be implemented. Many companies cannot respond quickly to delivery times, and in urgent situations, they can compress the shipping time to within 8 hours. There are also some small batch orders, and the question of whether PCBA processing manufacturers can undertake them.

2.The degree of specialization of the factory

PCBA processing is a complex process that requires coordination and cooperation from various departments, from PCB sampling to subsequent SMT, plug-in, and so on. Whether the factory has the ability to process products, the level of professionalism is particularly important.

Professional equipment: PCBA processing and production require very specialized equipment, such as high-speed mounting equipment, multi temperature zone reflow soldering, ICT online testing equipment, AOI testing equipment, etc., all of which are the foundation for ensuring production.

Process management: In addition to professional production equipment, printed circuit board assembly sampling also requires process management for professional quality control. Good PCBA SMT service manufacturers will be certified by ISO9001 quality management system, IATF: 16949 automotive quality management system, IPC-A-610E electronic assembly acceptance standard, etc., and will provide guidance on employee behavior through SOP job instructions and other materials and documents. By reviewing the factory’s business license, qualification certification, and other relevant documents, one can gain a general understanding of the factory’s quality control capabilities.

Professional testing process: In addition to professional equipment and process management, it is also necessary to have a complete testing process. As we all know, making samples is a delicate task. The assembly and placement of many electronic components, DIP, and even the soldering of many pins can be complicated throughout the entire process, and quality issues may arise. So it is necessary to check at all levels, strictly inspect quality defects, and “check for deficiencies and make up for them”. A circuit board assembly sampling company that values quality will be equipped with a complete testing process:

IQC incoming inspection, SPI solder paste inspection, online AOI inspection, SMT first piece inspection, appearance inspection, X-ray welding inspection, BGA device repair, QA inspection, anti-static storage and retrieval

3.Service awareness

A PCBA prototype manufacturer with good service awareness can proactively take responsibility, respond quickly, and solve problems for customers when they encounter problems. Not only should we provide good pre-sales service quality, but we also need thoughtful and comprehensive after-sales service.Circuirt board assembly sampling manufacturers provide semi-finished processing services, which are not real products. Therefore, the service awareness of a PCB board assembly sampling manufacturer is very important.

4.Price

The price of PCB assembly sampling is relatively transparent, with both high and low prices, but the lower the price, the better. Some PCBA sampling manufacturers choose to purchase genuine and original branded components, as well as implement strict quality control, which will increase the cost of processing; Some PCB assembly sampling manufacturers may cut corners in order to lower prices, resulting in unstable quality, poor delivery quality, and a high number of defective products. As the saying goes, you get what you pay for. We should choose a suitable and cost-effective PCBA sampling manufacturer based on our own situation.

5.Industry experience

Nowadays, the PCB assembly industry is in a stage of turbulence, with some poorly managed PCBA sample manufacturers closing down one after another. PCB board assembly manufacturers with years of industry experience have strong comprehensive strength and better service advantages. This needs to be analyzed specifically from the perspectives of customer feedback and partners.

Analyze from the perspective of customer feedback

The voices of customers we have worked with before can better reflect the strength of PCBA manufacturers, as well as their pre-sales and after-sales services. When looking for a PCBA manufacturer, it is important to first search for some information about the company online. If this supplier is really deceitful, it will definitely be exposed.

Analyze from the perspective of partners

How to learn about the partners of PCBA manufacturers and which ones are there? It’s difficult to find out offline, but we can check this information on the official website of PCBA service manufacturers. Nowadays, most companies showcase their successful cases to show their strength. At this point, we can gain a better understanding of the company by getting to know the clients they have previously worked with.