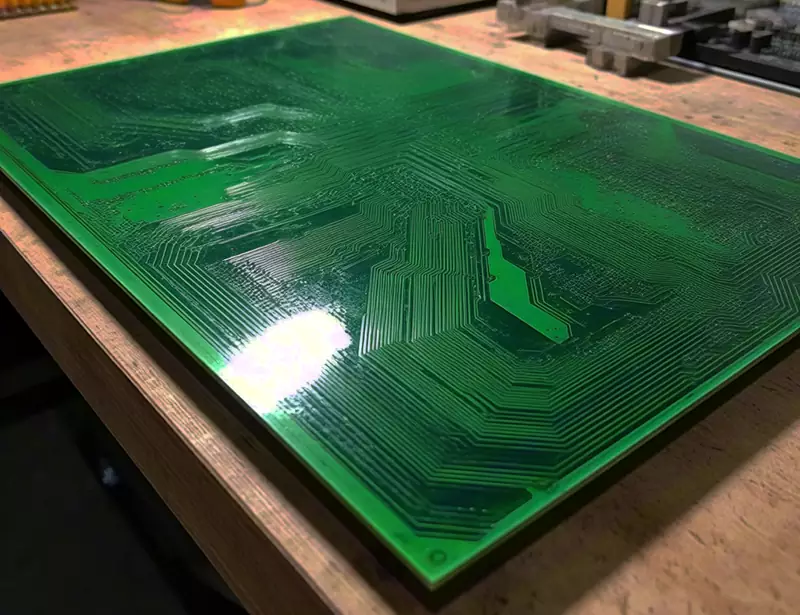

What is a FR4 PCB?A FR4 PCB refers to a printed circuit board utilising FR4 as both its substrate material and prepreg. FR-4 is a commonly employed PCB substrate material, serving as the abbreviation for glass fibre reinforced epoxy resin with a ‘Flame Retardant’ rating of 4.

‘FR-4’ denotes a flame-retardant material classification. It signifies a material specification where the resin must self-extinguish when subjected to combustion. It is not a material name but a grade designation. Consequently, numerous FR-4 grade materials are currently used in general circuit boards, though most are composite materials comprising so-called Tera-Function epoxy resin, fillers, and glass fibre.

Basic Manufacturing Capabilities

Layer Count and Thickness

Standard Layer Count: Supports 1-20 layer PCB manufacturing. HDI boards can achieve 1-3 levels of mechanical blind vias or laser blind vias.

Thickness Range: Board thickness 0.6-3.2mm, with specific thickness dependent on layer count (e.g., 1.6mm thick boards can withstand 5kg impact).

Tolerance Control: ±10% tolerance for board thickness ≥1.0mm; ±0.1mm tolerance for pcb board thickness <1.0mm.

Dimensions and Tolerances Maximum Dimensions: 520×600mm for single/double-sided, four-layer boards; 400×500mm for ≥6-layer boards.

Minimum Dimensions: Non-OSP boards ≥50×50mm, OSP boards ≥80×50mm.

Outline Tolerance: ±0.15mm (industry standard ±0.2mm).

Hole Processing Capabilities

Mechanical Drilling: Hole diameters 0.15–6.35mm (diameters >6.35mm achievable via reaming).

Laser drilling: Hole diameter 0.075–0.15mm (for >0.15mm, mechanical drilling recommended to reduce costs).

Hole position tolerance: ±0.075mm; PTH hole diameter tolerance ±0.075mm (crimp holes ±0.05mm).

Classification of FR4 PCBs

Based on glass transition temperature (Tg value)

The glass transition temperature (Tg) denotes the thermal threshold at which a solid material begins to transform, exhibiting rubber-like properties or softening. FR4 is categorised into three classes based on Tg: low Tg (approximately 135°C), medium Tg (approximately 150°C), and high Tg (approximately 170°C). Generally, a higher Tg value correlates with enhanced material reliability.

Based on Dielectric Loss (DF)

The magnitude of the dielectric loss factor (DF) directly influences FR4’s performance in high-frequency environments. A lower DF value reduces signal loss during high-frequency transmission, indicating superior performance. The DF values for FR4 laminates can be categorised as follows:

Standard Loss Materials: Df ≥ 0.02

Medium Loss Materials: 0.01 < Df < 0.02

Low-loss materials: 0.005 < Df < 0.01

Ultra-low-loss materials: Df < 0.005

Halogen-free FR4 PCB

Halogen-free FR4 PCB contains no halogen compounds, or only negligible amounts. Given the toxicity of halogens, such FR4 PCB materials have become a common choice today.

Copperless FR4

Copperless FR4 refers to circuit boards lacking copper layers and traces. Primarily serving an insulating function, it is more commonly employed as a stiffener within rigid-flex circuit boards.

By Structure or Design

FR4 PCB boards can be fabricated into various structural or design configurations, chiefly single-sided, double-sided, and multilayer circuit boards.

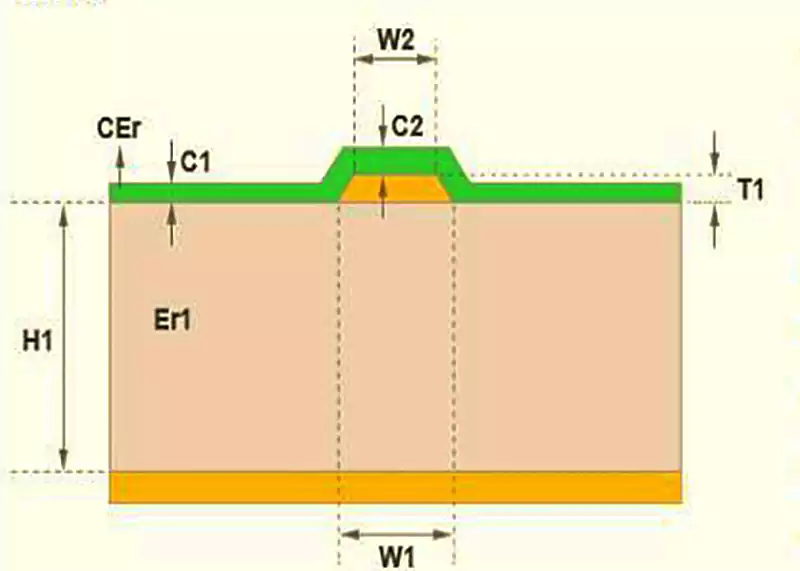

Single-sided printed circuit board: This represents the most fundamental design form for FR4 PCB sheets, consisting of a single copper layer supported by an FR4 core.

Double-sided printed circuit board: Featuring two conductive copper layers sandwiched between an FR4 laminate, components can be placed on both sides of the board. This configuration is suitable for applications requiring high component density.

Multilayer Printed Circuit Board: A more complex structure comprising multiple FR4 sheets, with layer counts ranging from 2 to 16 or more. To connect different layers, small holes known as vias are drilled through the board.

FR4 Properties:

Dielectric Constant (Dk): 3.8 – 4.7

Dissipation Factor (Df): 0.02 – 0.03

Volume Resistivity: Greater than 10¹³ Ω·cm

Dielectric Strength: 20 – 50 volts/mm

Tensile Strength: 350 – 500 MPa

Flexural strength: 400 – 600 MPa

Glass transition temperature (Tg): 130 – 180°C

Thermal conductivity: 0.3 – 0.4 W/m·K

RoHS and REACH compliance: Generally compliant

HDI compatibility: Supported by select variants only

FR4 PCB material possesses relatively high dielectric constant (Dk) and dielectric loss (Df), rendering it suitable for applications carrying signals up to 1GHz. However, among materials used in modern PCBs, its glass transition temperature (Tg) is relatively low. Regarding mechanical properties, it exhibits the excellent characteristics expected of rigid PCBs. Furthermore, it generally complies with ROHS and REACH standards, a feature common to most contemporary materials. It should be noted, however, that its support for HDI is limited to a few high-performance FR4 variants.

Precautions for Using FR4 Material Environmental Control:

FR4 material should be stored in a dry, cool, and well-ventilated environment, avoiding direct sunlight and high-temperature, humid conditions. Suitable environmental conditions generally involve air humidity not exceeding 70% and temperatures around 25°C.

Temperature Management: During use, observe the FR4 material’s operating temperature range and avoid exceeding its long-term service temperature to prevent material degradation or deformation.

Mechanical Stress: When designing and processing products made from FR4, avoid subjecting them to excessive mechanical stress. During installation and use, prevent mechanical damage such as impact or bending.

Electrical Performance Considerations: For high-frequency and high-speed signal transmission applications, fully account for the dielectric limitations of FR4 material. In high-voltage and high-current applications, monitor changes in its insulation properties to prevent breakdown or arcing phenomena.

Flame Retardancy and Environmental Considerations: Whilst FR4 possesses inherent flame retardancy, in specific applications—particularly those with stringent environmental requirements—the impact of combustion by-products on the environment and human health must be comprehensively evaluated. Appropriate protective measures should be implemented or more environmentally friendly materials selected.

Dimensional Accuracy Requirements: In applications demanding high dimensional precision, attention must be paid to the effects of FR4 PCB material’s hygroscopicity and temperature sensitivity on dimensional stability. Where necessary, higher-performance materials may be selected or specialised processing techniques employed.