Aluminium PCB is a unique metal-based copper-clad laminate comprising circuit layers, thermal insulation layers, and a metallic substrate. Utilising aluminium plate as the base material, copper conductive traces are formed on the surface through chemical etching or machining processes, creating a printed circuit board.

Composition of Aluminium PCB

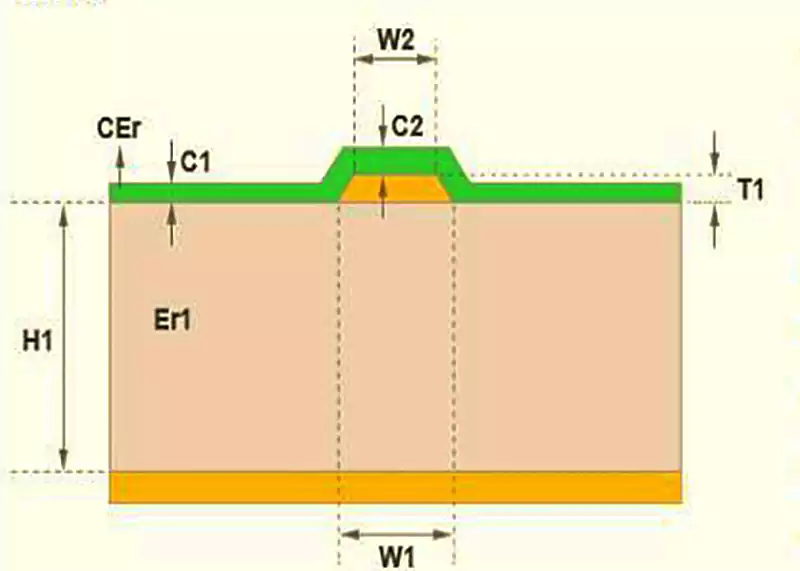

- Circuit Layer

The circuit layer (typically electrolytic copper foil) is etched to form printed circuits, facilitating component assembly and interconnection. Compared to conventional FR-4, aluminium PCB can carry higher currents at identical thicknesses and trace widths. - Insulation Layer

The insulation layer represents the core technology of aluminium PCBs, primarily serving bonding, insulating, and thermal conduction functions. It constitutes the primary thermal barrier within power module structures. Superior thermal conductivity within this layer facilitates heat dissipation generated during device operation, thereby reducing operating temperatures. This enhances module power handling capacity, reduces physical footprint, extends service life, and increases power output. - Metal Base Layer

The selection of metal for the insulating metal substrate depends on a comprehensive assessment of factors including thermal expansion coefficient, thermal conductivity, strength, hardness, weight, surface condition, and cost.

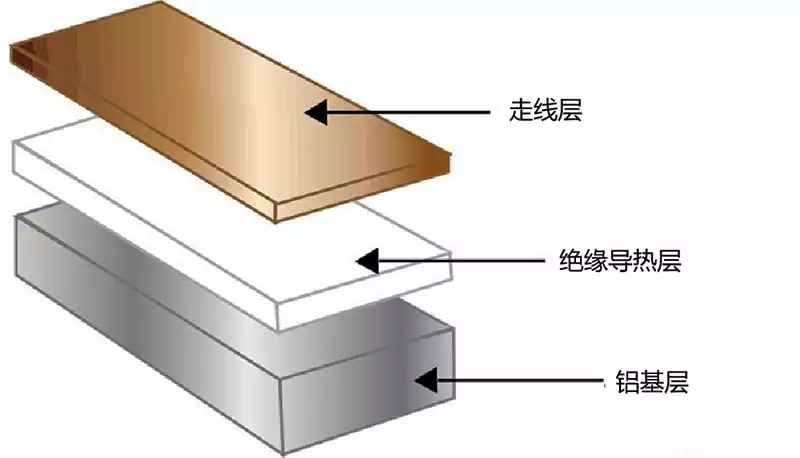

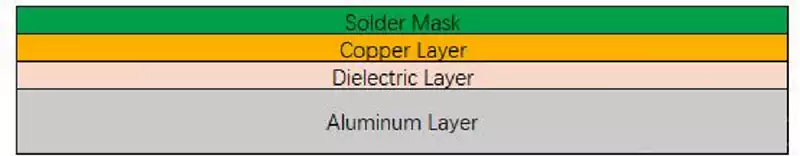

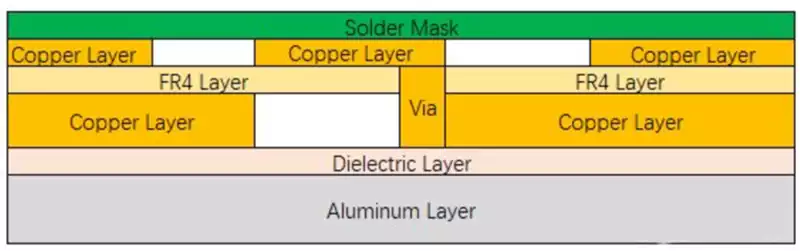

Structure of Aluminium PCB

The typical structure of an aluminium PCB is as follows: the top layer comprises the trace layer, the middle layer is the insulating thermal interface layer with excellent thermal conductivity, and the bottom layer consists of the aluminium base substrate.

Single-layer surface-mount aluminium PCB

The single-layer surface-mount aluminium PCB features the simplest structure, is the easiest to manufacture, and carries the lowest cost. Traces are directly etched onto the copper layer of the aluminium laminate. Heat transfers from components to the trace layer, passes through the intermediate insulating thermal interface layer, and is then conducted to the aluminium base layer.

Single-sided assembly with double-sided trace aluminium PCB

Single-sided assembly with double-sided trace aluminium PCB features two trace layers and insulating layers. Heat transfers from components to the first trace layer, then to the first insulating layer, to the second trace layer, to the second insulating layer, and finally to the aluminium layer.

Double-sided assembly with double-sided trace aluminium PCB

Occasionally, single-sided component placement on aluminium PCBs fails to meet requirements. Aluminium PCBs may be designed for double-sided mounting. In this laminate configuration, traces on both upper and lower layers must traverse the aluminium substrate. As aluminium is an excellent conductor, vias require insulation treatment, such as filling with insulating resin around the vias. Heat generated by components transfers from the components to the trace layer, then to the insulating layer, and finally to the intermediate aluminium substrate.

Principle of aluminium circuit boards:

Aluminium circuit boards achieve efficient heat dissipation and circuit integration through a three-layer structure:

Circuit layer: Surface-mounted power devices (e.g., MOSFETs, IGBTs) directly carry electrical signals.

Insulation layer: Utilises highly thermally conductive insulating materials (e.g., thermal adhesives, ceramic-filled polymers) to rapidly transfer heat generated by components to the metal substrate while providing electrical isolation.

Metal Base Layer: Typically aluminium or copper substrate, which dissipates heat via thermal conduction to the external environment (e.g., heat sinks, enclosures, or air), forming a heat dissipation pathway.

Heat Dissipation Pathway:

Device generates heat → Insulation layer conducts heat → Metal base layer dissipates heat → External environment

(Key point: The insulation layer must balance high thermal conductivity with electrical insulation properties)

Performance comparison with conventional materials

| Comparison dimension | Aluminium PCB | FR-4 (traditional fibreglass board) | Thick-film ceramic circuits |

| Thermal conductivity | Extremely low thermal resistance (high thermal conductivity) | High thermal resistance (low thermal conductivity) | Moderate thermal conductivity, but highly brittle |

| Mechanical properties | Excellent (impact-resistant, bend-resistant) | Ordinary (prone to moisture damage and deformation) | Highly brittle (easily broken) |

| Process adaptability | Perfectly suited for SMT | Suitable for SMT but with limited heat dissipation | Requires specialised processes, resulting in high costs. |

| Cost and Volume | Reduce the number of heat sinks to lower hardware costs | Requires additional thermal management design; bulky | High material costs, volume constraints |

Distinctive Advantages

Environmental Compliance

Complies with RoHS (Restriction of Hazardous Substances Directive), lead-free and halogen-free, meeting global environmental standards.

SMT Process Compatibility

High surface flatness, suitable for automated placement, enhancing production efficiency.

Excellent high-temperature resistance, withstands reflow soldering temperatures (typically ≥260°C).

Thermal Management Optimisation

Thermal diffusion treatment: Uniformly disperses heat through the metal substrate, preventing localised overheating and reducing module temperatures by 10-30%.

Extended lifespan: Each 10°C reduction in temperature approximately doubles device longevity (Arrhenius model).

Enhanced Power Density: Reduced thermal management requirements enable narrower component spacing, increasing power output per unit area.

Cost and Volume Optimisation

Hardware Simplification: Eliminates heat sinks, thermal interface materials (TIM), etc., lowering BOM costs.

Compact Form Factor: Thickness as low as 0.5mm, suitable for space-constrained designs (e.g., LED lighting, power modules).

Assembly Streamlining: Reduced assembly steps decrease labour and time expenditure.

Circuit Integration Optimisation

Power and Control Circuit Integration: Integrates high-voltage power circuits with low-voltage control circuits on a single substrate, minimising signal interference.

Modular Design: Supports Multi-Chip Modules (MCM), enhancing system integration.

Mechanical Durability

Impact and vibration resistant, suitable for harsh environments such as automotive and aerospace applications.

When replacing ceramic substrates, withstands higher mechanical stresses, reducing breakage risks.

Application Domains of Aluminium PCBs

- LED Lighting: LED luminaires generate substantial heat during operation. Aluminium PCBs efficiently dissipate this heat, ensuring stable performance and extended service life. Consequently, they are widely adopted in LED lighting applications.

- Power Modules: Power modules similarly generate substantial heat during operation. Aluminium PCBs provide excellent thermal dissipation, ensuring the stability and reliability of power modules.

- Automotive Electronics: Automotive electronic systems face harsh environments characterised by high temperatures, humidity, and vibration. Aluminium PCBs, owing to their superior thermal conductivity and stability, represent an ideal choice for the automotive electronics sector.