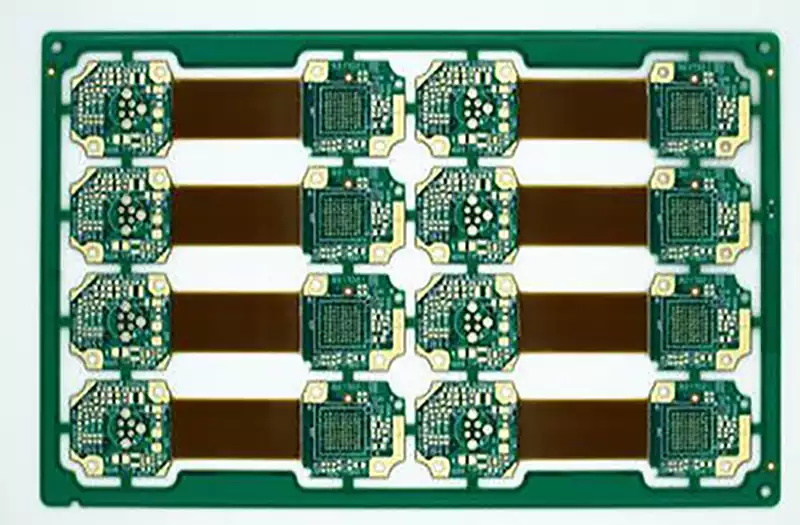

Rigid flex pcbs, as the name suggests, are specialised circuit boards formed by combining rigid circuit boards with flexible circuit boards through specific manufacturing processes.

This combination not only retains the high strength, high reliability, and multi-layer routing advantages of rigid circuit boards but also endows the board with bendable and foldable characteristics in specific areas.

The ‘rigid’ portion: Typically employs materials akin to conventional PCBs (such as FR-4), providing structural integrity for mounting primary electronic components requiring stable support (e.g., chips, connectors, large capacitors).

The ‘flexible’ section: Typically employs flexible substrates like polyimide (PI), characterised by being lightweight, thin, bendable, and foldable. This section connects different rigid areas or facilitates three-dimensional routing within the device.

Integration is key: Specialised adhesives and lamination processes seamlessly and reliably fuse rigid and flexible sections into an interconnected monolithic structure, eliminating the need for additional connectors and cables.

Core materials for rigid flex pcbs comprise the rigid substrate FR4 (fibreglass-reinforced epoxy laminate) and the flexible substrate polyimide (PI).

FR4 provides robust mechanical support and reliable electrical insulation, while PI imparts exceptional flexibility and high-temperature resistance. These materials are tightly bonded through processes like compression lamination, yielding the uniquely performing rigid flex board.

FCCL (Flexible Copper Clad Laminate)

Core Material Composition

The core material of FCCL consists of polyimide (PI) or polyester (PET) film combined with copper foil (including electrolytic copper foil and rolled copper foil).

Classification

Adhesive-bonded FCCL: Copper foil is bonded to the substrate using an adhesive (such as epoxy resin). This type offers relatively lower costs but faces limitations in thickness and flexibility.

Adhesive-Free FCCL: Copper foil is chemically bonded directly to the substrate. It achieves thinner profiles (e.g., down to 12.5μm) and superior flexibility, making it ideal for high-density designs such as foldable screen products.

Common Substrate Types

Polyimide (PI)

Advantages: Exceptional high-temperature resistance, withstanding 260°C for extended periods and up to 400°C for short durations; strong tear resistance; excellent electrical insulation; high dimensional stability with moisture absorption between 0.2–0.4%.

Disadvantages: Relatively high cost, accounting for 30–40% of FCCL expenses; requires attention to potential dimensional expansion upon moisture absorption.

Applications: Commonly used in mobile phone motherboards, automotive electronics, and aerospace sectors (e.g., Kapton® HN series).

Key Adhesive Selection Criteria

Thermosetting adhesives (e.g., epoxy resins): Offer high-temperature resistance and strong bonding strength, suitable for reflow soldering processes.

Thermoplastic adhesives (e.g., polyester): Provide good flexibility but inferior temperature resistance (below 120°C), primarily used for temporary protective applications.

Polyester (PET)

Advantages: Low cost, approximately one-third to one-fifth of PI’s cost; good flexibility; satisfactory water resistance.

Disadvantages: Poor high-temperature performance with a melting point of 250°C and short-term temperature resistance limited to 150°C; prone to shrinkage upon heating, with a shrinkage rate between 1–2%.

Application Areas: Primarily used in consumer electronics (e.g., membrane switches) and low-cost sensors.

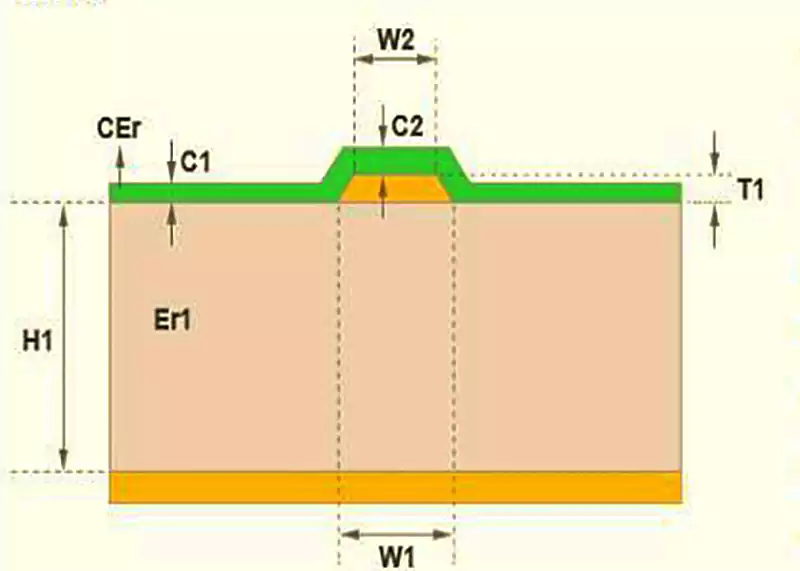

Coverlay

Function Description

Coverlays primarily protect circuits, provide insulation, and enhance mechanical strength.

Material Selection Key Points

PI Coverlay: Matches the base PI substrate, offering high-temperature resistance and corrosion resistance, suitable for scenarios demanding long-term reliability.

Epoxy (FR4) Coverlay: Lower cost but with comparatively reduced flexibility and heat resistance, predominantly used in rigid board areas.

Acrylic Adhesive: Excellent transparency, suitable for display modules (e.g., OLED screen bonding).

Characteristics of rigid flex pcbs

Advantages:

1) Suitable for folding structures, such as foldable phones and slider phones.

2) Eliminates connectors between flexible and rigid boards, enhancing connection reliability.

3) Enables 3D assembly requirements.

4) Simplifies assembly processes by reducing component count and steps.

5) Facilitates product miniaturisation due to thinner materials.

Disadvantages:

1) Currently higher cost.

2) Limited suppliers, particularly for HDI Rigid-Flex.

3) Less design experience available.

Primary Application Areas of rigid flex pcbs

Consumer Electronics

Rigid flex pcbs are extensively employed in smartphones, tablets, and wearable devices. Within smartphones, they connect critical components such as cameras, enabling compact designs and enhanced performance. In foldable devices, their bendable properties are pivotal for flexible screen deployment, driving the advancement of foldable display technology.

Automotive Electronics

Within automotive electronics,rigid flex pcbs play a pivotal role, particularly in new energy vehicles. They are extensively employed in core components such as in-vehicle displays, sensors, and battery management systems, ensuring stable operation in demanding environments. Furthermore, they are widely integrated into ADAS and electric vehicle control modules, elevating automotive safety and intelligence.

Medical Devices

Rigid flex pcbs find extensive application in medical equipment such as endoscopes, cardiac pacemakers, and portable diagnostic devices. Their high precision and reliability ensure safe, stable operation – enabling precise image transmission and manipulation within endoscopes, for instance, thereby enhancing diagnostic accuracy and efficiency.

Industrial Automation

Within industrial automation,rigid flex pcbs play a pivotal role, particularly in industrial robotics and sensor control modules. Their high-density integration and exceptional mechanical properties robustly safeguard industrial equipment against complex, harsh environments. Furthermore, within industrial automation systems, these boards are employed in programmable logic controllers (PLCs), significantly enhancing automation levels and operational efficiency.

Aerospace

Within aerospace applications,rigid flex pcbs occupy a pivotal position, demonstrating particular prominence in satellite communication equipment and flight control systems. Their lightweight design and exceptional reliability ensure stable operation of aerospace equipment under extreme environmental conditions. For instance, within satellite communication systems,rigid flex pcbs undertake the critical tasks of high-speed signal transmission and data processing, significantly enhancing mission execution efficiency and safety.

Internet of Things (IoT)

Within IoT devices,rigid flex pcbs find extensive application, commonly appearing in smart home systems and edge computing equipment. Their high-density integration and excellent signal integrity ensure efficient device operation and stable data transmission. In smart homes, for instance, they enable intelligent control and data transmission, enhancing automation capabilities and user experience.