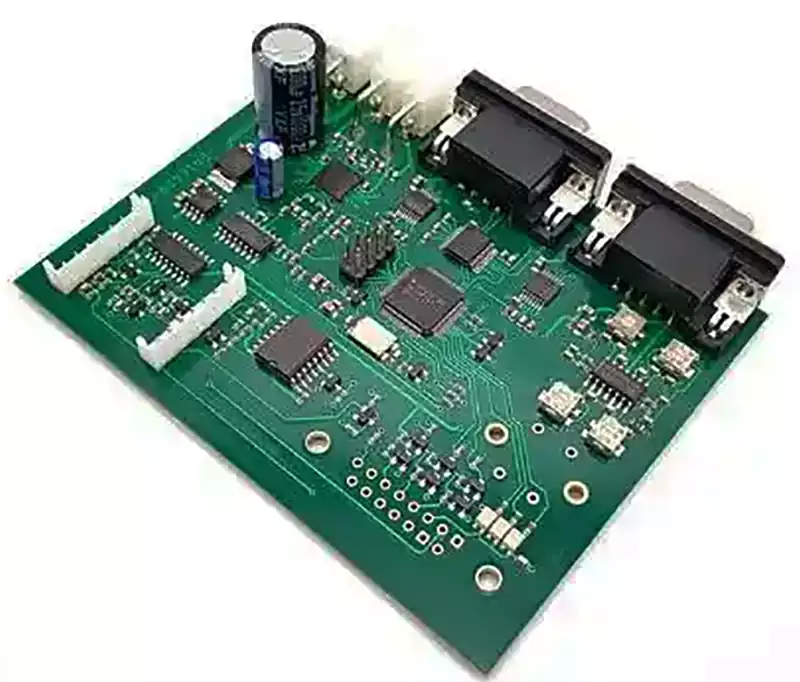

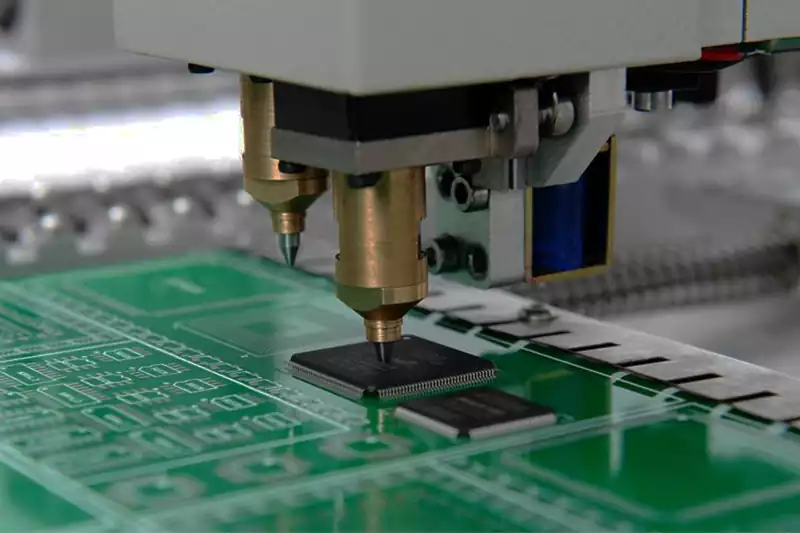

What is PCBA testing? PCBA testing (Printed Circuit Board Assembly Test), also known as circuit board assembly inspection, refers to a series of electrical and functional tests conducted on the fully assembled circuit board after all electronic components (such as chips, resistors, capacitors, etc.) have been placed and soldered onto the printed circuit board.

In essence, its core purpose is to ensure the assembled circuit board functions correctly and is free from manufacturing defects.

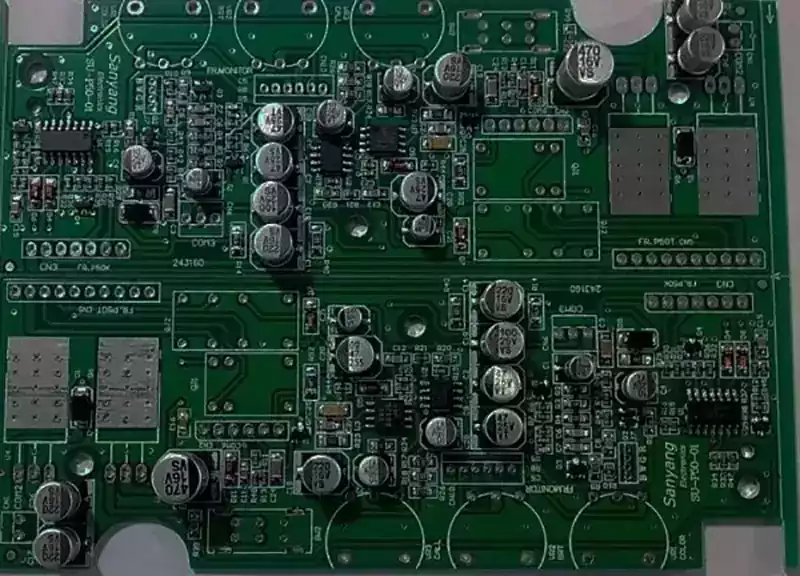

Test Subject: The entire PCBA board with all components soldered in place (i.e., the bare PCB board without components + all components fully soldered).

Primary PCBA Testing Methods:

ICT (In-Circuit Tester) Testing:

This automated testing system for assembled circuit boards operates by contacting test probes with pre-designated test points (Q) on the PCB. It comprehensively inspects the PCBA’s circuit integrity, including open circuits, short circuits, and the soldering quality of all components. This testing can be subdivided into open circuit testing, short circuit testing, resistance testing, capacitance testing, diode testing, transistor testing, field-effect transistor testing, and IC pin testing (e.g., Test Connect Check, BasicScan Bist). It detects faults such as missing or misplaced components, parameter deviations, solder bridging, and board open/short circuits. Specific faulty components or open/short locations are clearly displayed to the user via printer or screen.

FCT (Functional) Testing:

This test simulates the actual functionality of the entire PCBA board and utilises IC programming to uncover potential hardware and software issues, requiring a corresponding test fixture. In essence, FCT testing involves applying appropriate stimulus signals to the target board under test and measuring whether its output responses meet expected requirements.

The fundamental FCT testing process encompasses instrument connection, measurement initiation, data acquisition, data processing, data analysis, and result output. During testing, diverse test environments are constructed to comprehensively execute all functional assessments.

Fatigue Testing:

Subjects PCBA boards to high-frequency, prolonged continuous operation to observe potential failures and assess failure probability.

Ageing Testing:

Keeps PCBA boards and electronic products powered and operational for extended periods to detect any failure or malfunction issues.

Functional Testing:

Each function of the PCBA is individually tested to ensure proper operation, including switch functionality, LED display, and communication interface performance.

Flying Probe Testing:

Both flying probe testing and in-circuit testing (ICT) are widely recognised as effective testing methods, capable of identifying production quality issues. However, flying probe testing has proven to be a particularly cost-effective approach for enhancing circuit board standards.

Why is PCBA testing conducted after pcb circuit boards complete their manufacturing processes?

- To ensure circuit functionality

The primary purpose of PCBA testing is to verify whether the circuit board’s functionality meets design specifications. Functional testing (FCT) simulates the board’s operational state in real-world applications, ensuring all electronic components and circuits function cohesively. Issues such as short circuits, open circuits, or abnormal electrical parameters can be promptly identified and rectified through testing, preventing defective products from entering the market. - Enhancing product stability

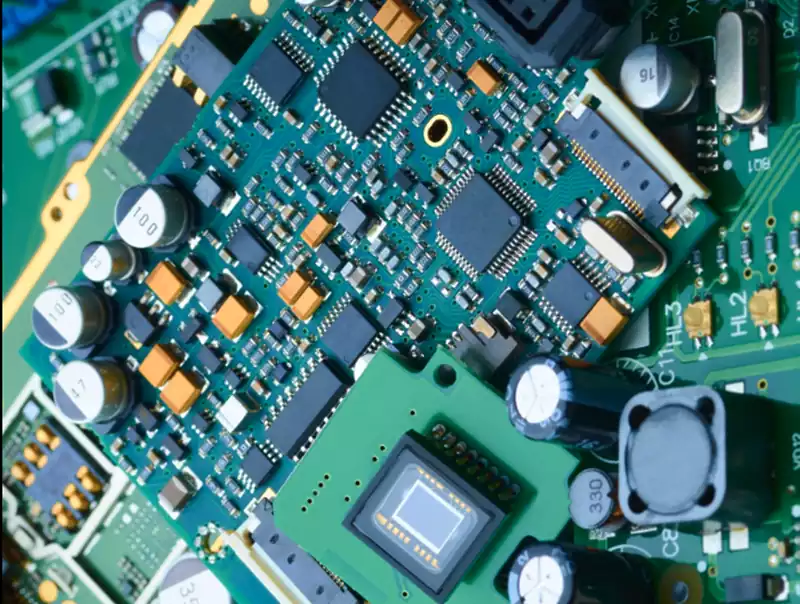

PCBA testing extends beyond functional verification to include reliability assessments such as thermal cycling and vibration testing. These evaluations simulate extreme environmental conditions to gauge circuit board reliability. By identifying components prone to failure under harsh conditions, the stability of the final product is significantly improved, reducing the likelihood of malfunctions. - Identifying Manufacturing Defects

Even within highly automated production processes, manufacturing defects remain difficult to eliminate entirely. Defects such as poor soldering, misplaced components, or detached pads may occur during manufacturing. PCBA testing, utilising methods like In-Circuit Testing (ICT) and visual inspection, efficiently detects these manufacturing flaws. Prompt rectification not only enhances product quality but also reduces costs associated with subsequent rework and product scrapping. - Alignment with Customer and Industry Standards

Numerous industries and customers impose stringent quality requirements, making PCBA testing a critical step in meeting these standards. Through PCBA testing, products can be assured to comply with relevant industry regulations (such as ISO and IPC standards) and meet specific customer specifications. This not only enhances product competitiveness in the marketplace but also strengthens customer trust in the manufacturer. - Reduction in Rework Expenditure

Without thorough PCBA testing, undetected issues may surface after assembly completion or during user operation. This not only increases rework costs but may also negatively impact brand reputation. Conducting comprehensive PCBA testing post PCB fabrication enables the identification and resolution of problems during production, thereby effectively reducing rework rates and after-sales expenses.